Listing ID #3903378

Company Information

Ask for more detail from the seller

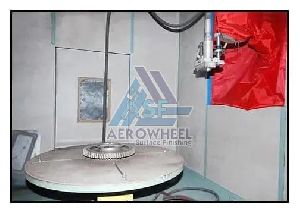

Contact Supplier- Shot Peening machine is used for surface peening of leaf springs to give extra life to the spring.

- The leaf spring is placed on the conveyor belt, which moves at a speed of 3 meters/minute.

- In the main blasting chamber concave surface of the spring is bombarded with very high velocity shots.

- The impact of the shots leaves a impinge impression on the surface which increases the fatigue life of the spring by 50%

| Main parts of the machine: |

| Main chamber/ Blasting chamber: Here the spring is subjected to shot peening. The inner side is protected by liners made of rubber and M.S. Care has to be taken to see that the condition of the liner is inspected every week and necessary replacement be done wherever wear & tear is observed. |

| Shot Peening Wheel: Here the shots are thrown at very high velocity by the wheel and blades. Main parts for inspection are: Cage, Impeller, Blades, bare wheel, bearing assembly, V belts. The blades should be balanced to avoid vibrations and breakage. |

| Pneumatic Cylinder: This operates on compressed air, which is supplied through a solenoid valve. The main function is to start supply of the shots and stop supply when shutting off the machine. |

| Separator: This has a screen to separate the big unwanted particle, which may have accidentally entered the shots. |

| Bucket elevator: This conveys the shots from the bottom of the machine to the separator at the top. The bucket belt can be tightened by the screws at the top. The belt and the buckets have to be inspected every 15 days for wear. |

| Screw conveyor: This conveys the shots to the bucket elevator. |

| Main conveyor system: This conveys the leaf springs through the machine. There is a variable speed drive unit for controlling the speed of the belt. |

| Doors: They are provided for inspection of the liners in the main chamber. These are fitted with limit switches, which provide safety that the machine will not operate when the doors are open. |