Listing ID #6085955

Company Information

Ask for more detail from the seller

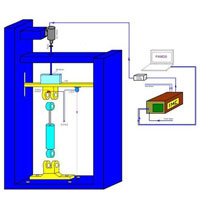

Contact SupplierThe machine is fabricated with Mild steel of a very robust design to provide necessary mechanical strength and rigidness. The machine produces the shock pulses using compressed air to force the platform to impact on the elastomer pads (Half-Sine Programmer Pads)which are placed between the platform and anvil of the impact area to produce half-sine pulses, Lead pellets are placed to generate sawtooth pulses and pneumatic cylinders are used to generate square pulses. The drop height and the air pressure are responsible to generate the desired acceleration.

Shock Test Machine is a versatile test equipment to carry out shock tests in accordance with various National & International standards e.g. IS, MIL, EN, ISO, IEC, DEF & ASTM Standards.

The lifting of the platform is done by pneumatic cylinders, the drop height is determined by the desired acceleration level. In a shock test due to the rebounce action secondary shocks may occur, which are totally unacceptable by most of the test standards. Fail safe brakes are used as a rebounce brake and as a quick release device to avoid secondary and tertiary shocks. The shock test machine is isolated from the ground by heavy duty shockers and shock absorbers. The Shock test machine is supported by a PC based intelligent Instrumentation system to control, monitor and analyse acquired shock test waveforms. The system has 4 channels to monitor the shock pulses generated which are expandable upto 16 channels.

Advantages for you

Customizable Reliable Solutions:Key features

Efficient performance:Key features

User Friendly:Key features

PC Based Instrumentation System

Shock-Test-Machine-control Tarang PC based instrumentation system provides an easy control, monitoring and waveform analysis to be done. The control of the machine is very user friendly and incorporates various safety interlocks for safe operation of the machine. The test report of any test performed can be viewed and printed easily. The Shock Analysis software is specially designed for the analysis of waveforms generated. Shock Response Spectrum Analysis can also be done with this software.

| Model | TSTS - 6060 | TSTS - 7570 | TSTS - 7575 | TSTS - 1010 |

|---|---|---|---|---|

| Table Size | 600 x 600 mm | 750 x 750 mm | 750 x 750 mm | 1000 x 1000 mm |

| Payload Capacity | 200 Kg | 250 Kg | 500 Kg | 1000 Kg |

| Payload Height | unlimited | unlimited | unlimited | unlimited |

| Max Payload Size | 600 x 600 mm | 750 x 750 mm | 750 x 750 mm | 1000 x 1000 mm |

| Insert Pattern | 100 x 100 mm Matrix | 100 x 100 mm Matrix | 100 x 100 mm Matrix | 100 x 100 mm Matrix |

| Stroke Length (Max) | 300 mm | 350 mm | 350 mm | 450 mm |

| Velocity Change No load | 7 m/s | 7 m/s | 10 m/s | 15 m/s |

| Velocity Change Full Load | 5 m/s | 5 m/s | 8 m/s | 8 m/s |

| Standard Test* | 20’g’ – 11’ms’ 30’g’ – 20’ms’ 40’g’ – 6’ms’ 50’g’ – 11’ms’ 50’g’ – 18’ms’ 100’g’ – 6’ms’ 150’g’ – 3’ms’ 200’g’ – 3’ms’ |

|||

| Pulse Shape | Half Sine Optional - Sawtooth / Square wave / Trapezoidal Waveform | |||

| Shock Rate | 1-8 shocks/min | 1-8 shocks/min | 1-8 shocks/min | 1-8 shocks/min |

| Max Deviation of specimen from table centre | 30 mm | 30 mm | 30 mm | 30 mm |

| Machine Mass | 4000 kg | 4500 kg | 5500 kg | 6500 kg |

| Dimensions (mm) | 900*900*1500 | 1000*1000*1600 | 1000*1000*1600 | 1500*1500*2000 |

| Utilities required | Plant air or bottled Nitrogen 6-8 bar 410V, 3 -phase 50 Hz | |||

| Safety Interlocks | Mains Input Over & Under Voltage, Phase drop, programmer pad change protection, over travel, Fail safe brake | |||