Listing ID #4257310

Company Information

Ask for more detail from the seller

Contact SupplierValgro-Hyzer deburring machine is meant especially for deburring and cleaning sharp corners, hole edges and irregular parameters from sheet metal component without damaging of the metal surface. This machine is available with multi-stage brushing head.

A burr is a raised edge or small pieces of material remaining attached to a workpiece after a modification process.

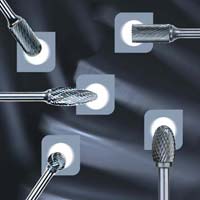

It is usually an unwanted piece of material and when removed with a deburring tool in a process called 'deburring'. Burrs are most commonly created after machining operations, such as grinding, drilling, milling, engraving or turning.

These procedures often create ragged edges. The raised particles and shavings that appear when metal blanks are machined are referred to as burrs, and the process by which they are removed is known as deburring.

Deburring is important for Safety & quality, aesthetics, functionality, and the smooth operation of working parts. since even a small notch can cause moving parts to catch, creating the potential for accident, injury, or unnecessary delay in production. Rough edges can also cause injury when individuals are required to handle blanks. Each of these preventable problems can cost companies a great deal of money.

Our surface preparation abrasives brush manufacturing experience has allowed us to build deburring machine with all the necessary technical devices required to obtain a perfect finish from small parts to larger area.

| Model "SAMARTH" | DB 24 BABY | DB 32 HD | DB 50 HD | Eco 12 (Light) | Kleen Burr |

|---|---|---|---|---|---|

| Brush Station | Two station | Single station | Single station | Two Station | Off Hand Application |

| System | Dry | Dry | Dry | Dry | Dry |

| Total Dimensions(H X W X L)) @ | 1150mm x 1350mm x 1100mm | 1300mm x 1350mm x 1000mm | 1600 mm x 2200 mm x 1000 mm | 600 x 400 x 450 mm | 1150 x 800 x 450 mm |

| Machine Weight @ | 800 Kg | 1400 Kg | 6000 Kg | 200 kg | 800 kg |

| Working Width | 600 mm | 800 mm | 1270 mm | 300 mm | 300 mm |

| Sheet size (minimum) Length | 125 mm | 250 mm | 250 mm | 125 mm | --- |

| Sheet thickness Min / Mix | 0.5 to 5 mm | 0.8 to 5 mm | 0.8 to 15 mm | 0.8 to 2 mm | --- |

| Brush Dimensions (Od x Width x ID) | 125 mm x 610 mm | 225 mm x 750 mm | 225 mm x 1250 mm | 100 mm x 300 mm | 300mm x 300mm |

| Brushing speed | Adjustable | Adjustable | Adjustable | Adjustable | Adjustable |

| Conveyor width | 610 mm | 850 mm | 1300 mm | 300 mm | --- |

| Conveyor speed | Variable | Variable | Variable | Standard | --- |

| Electrical parameter | 110-230V, 50-60Hz | 110-230V, 50-60Hz | 110-230V, 50-60Hz | 110-230V, 50-60Hz | 110-230V, 50-60Hz |

| Electrical mains | 440V, 50-60Hz | 440V, 50-60Hz | 440V, 50-60Hz | 440V, 50-60Hz | 440V, 50-60Hz |