Listing ID #3910079

Company Information

Ask for more detail from the seller

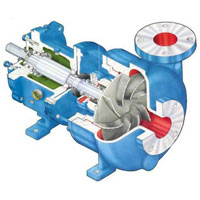

Contact SupplierThe AM / BM - Series Positive Displacement Progressive Cavity Screw Pumps has unique pumping principle applied employs a highly precision manufactured Metallic Single helical rotor turning inside a double internal helical resilient stator. Thereby forming cavities confined by a “Sealing Line” which is maintained at stand still and during rotation. While the rotor rotates in the stator, the cavity formed between them progresses form suction to delivery side, gently carrying the medium.

| Material of Construction |

|

| Characteristics and Salient Features | Go to top |

It is suitable for dosing and metering duties because of its sturdy and smooth flow with slight pulsation. Stator is metal bonded, guarantees high efficiency, pressure and improved life.