Listing ID #7451788

Company Information

Ask for more detail from the seller

Contact SupplierA screw feeder is a mechanical device used to transport materials, typically in a controlled manner, from one location to another. It is commonly used in industrial processes such as food processing, chemical production, and mining.

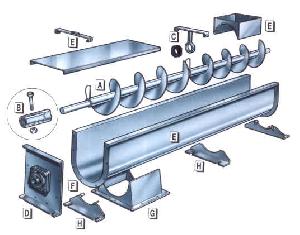

The screw feeder consists of a rotating screw or auger, which moves the material along a tube or trough. The screw is powered by an electric motor, and the speed and direction of rotation can be controlled to regulate the flow rate and direction of the material. The material is typically fed into the screw feeder from a hopper or other storage container.

Screw feeders can be designed to handle a wide range of materials, including powders, pellets, and granular materials. They are often used in conjunction with other equipment, such as a vibrating feeder or a hopper, to ensure a consistent and controlled flow of material.

Screw feeders can be used for a variety of purposes, including metering, blending, and conveying materials. They are also used in applications where precise control of material flow is required, such as in the production of pharmaceuticals or in the handling of hazardous materials.

Features :

Screw feeders can come with a variety of features depending on the specific application requirements. Some of the common features of screw feeders include:

Overall, screw feeders can be customized to meet the specific needs of a wide range of industries and applications. By selecting the right features for your application, you can ensure reliable and efficient feeding of materials.

Cleanx Agro Solution, a partnership company founded in 2019 by Mr. Chintan Patel, Mr. Tarun Patel, Mr. M.B. Unjhawala, and Mr. Furgan Khan, leverages the diverse expertise of its founders to deliver superior agro processing machinery. Based in Mahesana, Gujarat, our company has garnered a solid reputation for working closely with clients to develop products that enhance efficiency, effectiveness, and profitability while upholding the highest ethical standards.

At Cleanx Agro Solution, our commitment to quality and innovation is the cornerstone of our business. We pride ourselves on providing comprehensive turnkey solutions that encompass design, manufacturing, and testing within our state-of-the-art facilities. Our motto, 'Outline your Needs; We will do the Rest,' reflects our dedication to delivering tailor-made products that precisely meet our clients' requirements. Our manufacturing plant boasts a fully automated assembly line equipped with the latest machine tools and equipment, ensuring that our products adhere to the highest industry standards.

Our extensive product range includes Gravity Separators, VFD Operated Gravity Separators, PLC Operated Gravity Separators, Five Fan Gravity Separators, Cyclone Separators, Horizontal Cyclone Separators, Conical Cyclone Separators, Vibro Classifiers, Double Deck Vibro Classifiers, Triple Deck Vibro Classifiers, Bucket Elevators, Screw Conveyor Systems, Screw Feeder Systems, Moustache Tile Cutters, Rotary Air Valves, Aspiration Channel Cleaning Machines, Centrifugal Fans, Air Boxes, Duct Fittings, and Steel Spoutings.

Each product is designed with a focus on innovation and quality, supported by our in-house R&D department, which ensures compliance with the latest technological advancements and environmental guidelines set by the Government of India. At Cleanx, quality is a top priority. Their commitment starts with each individual employee and is ingrained in every aspect of their operations. By implementing best practices, we achieve optimal cost control and faster turnaround times.

Innovation is at the core of our business. Their design and manufacturing setup is optimized for great versatility, from concept development to design, scaling methods, and production. This allows them to offer custom-made products that precisely meet your specific requirements. At Cleanx Agro Solution, we strive to exceed client expectations by fostering a culture of quality and innovation, ultimately delivering machinery that stands out in the agro processing industry.