Listing ID #7230989

Company Information

Ask for more detail from the seller

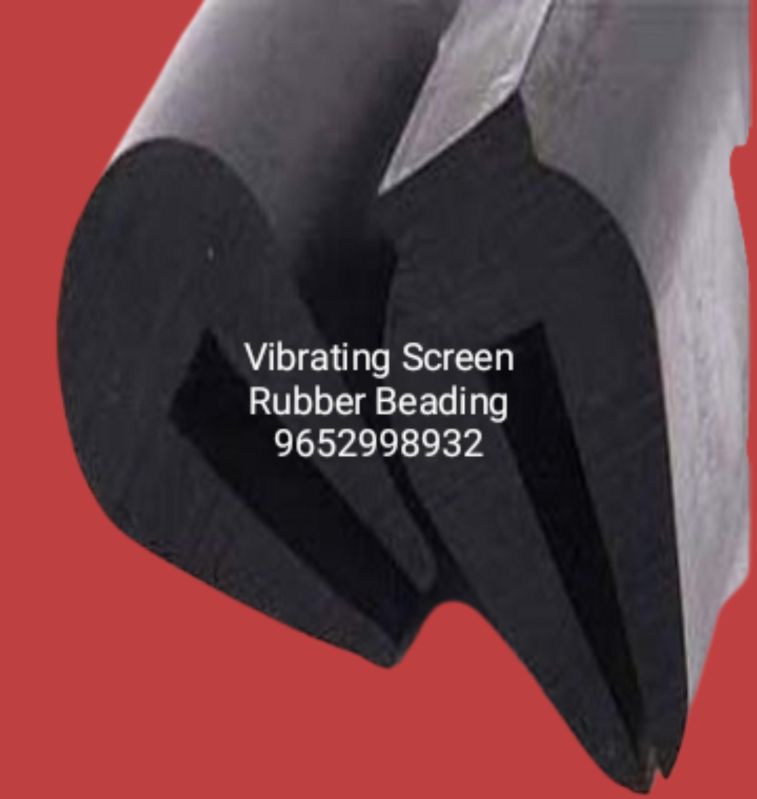

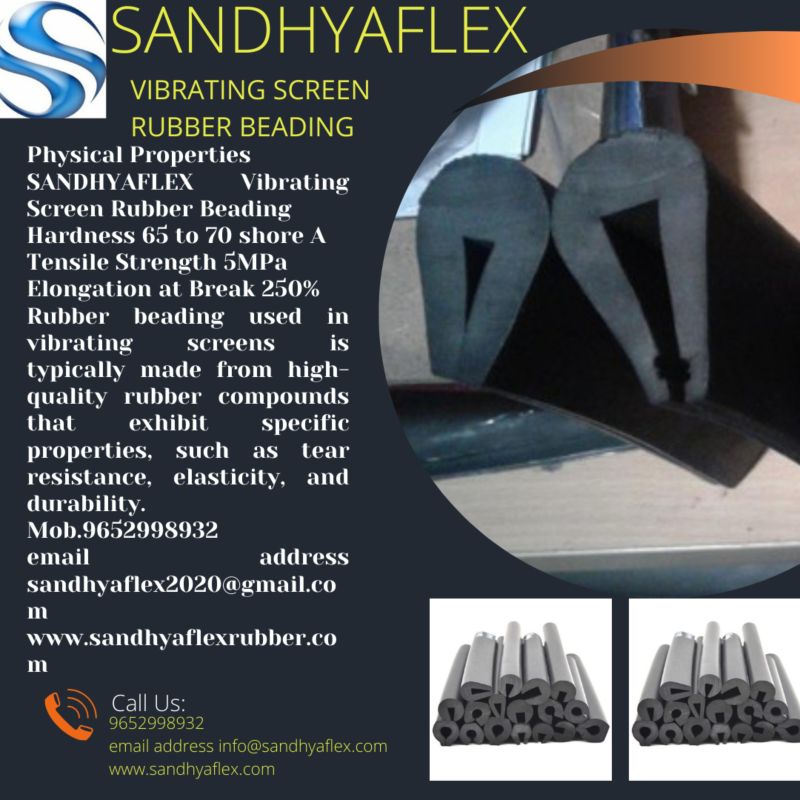

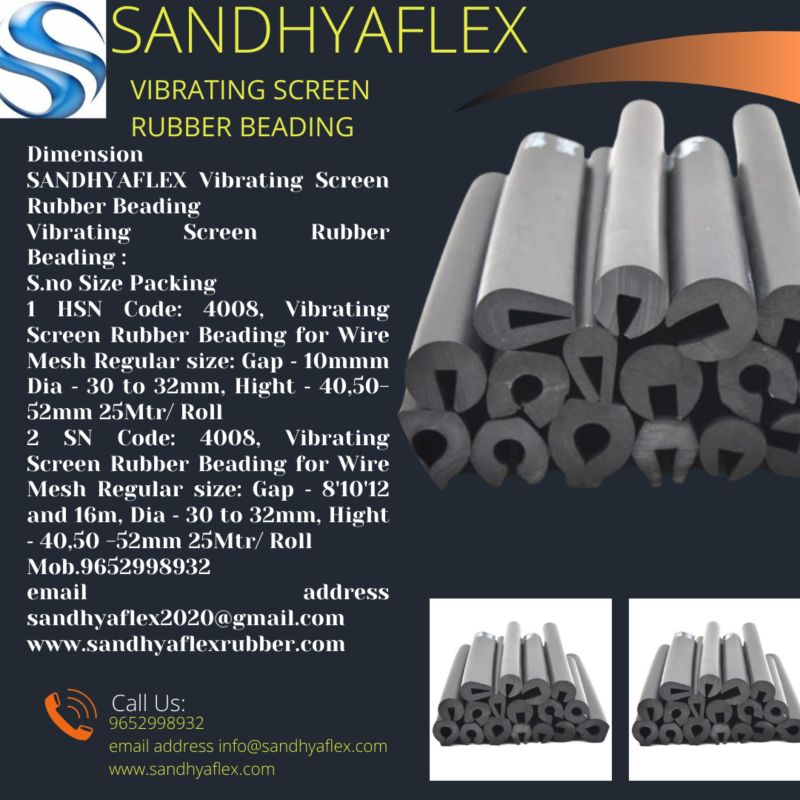

Contact SupplierThe use of rubber beading in vibrating screens offers several advantages that contribute to the efficiency, longevity, and functionality of the screening process. Here are the key advantages of vibrating screen rubber beading: 1. **Enhanced Sealing Properties:** Rubber beading acts as a sealant, effectively closing the gaps between screen panels or mats. This sealing prevents material leakage, ensuring that the screened material remains within the designated screening area without spillage. 2. **Reduced Material Bypass:** By securely fitting onto the edges of screen panels, the rubber beading prevents material from bypassing the screening surface. This ensures that the screened material is thoroughly processed without allowing undersized particles or fines to escape. 3. **Minimized Wear and Tear:** The use of rubber beading helps protect the edges of screen panels from abrasion and damage caused by constant movement and contact. This minimizes wear and tear on the screen components, prolonging the lifespan of the vibrating screen. 4. **Vibration Damping:** Rubber beading absorbs vibrations generated during the screening process. This damping effect reduces excessive vibrations, leading to smoother operation of the vibrating screen and reducing stress on the equipment, thus enhancing its durability. 5. **Noise Reduction:** The absorption of vibrations by rubber beading also contributes to reducing noise levels produced by the vibrating screen. This is beneficial in creating a quieter working environment, improving comfort for workers and meeting noise regulations. 6. **Easy Installation and Replacement:** Rubber beading is designed for easy installation, fitting snugly onto the edges of screen panels. This facilitates quick installation and replacement when necessary, reducing downtime during maintenance or replacement. 7. **Customization and Compatibility:** Available in various profiles and sizes, rubber beading can be customized to fit different types of screen decks and panel configurations. It is compatible with a wide range of vibrating screen models used in various industries. 8. **Weather and Chemical Resistance:** The rubber material used in vibrating screen beading is often resistant to weathering, oils, chemicals, and other harsh substances commonly encountered in industrial environments. This ensures its integrity and functionality over time. 9. **Improved Screening Efficiency:** Properly installed rubber beading ensures a tighter seal, reducing the risk of material spillage and enhancing the efficiency and accuracy of the screening process by maintaining a consistent screening surface. 10. **Cost-Effectiveness:** By prolonging the lifespan of the vibrating screen components, minimizing maintenance needs, and preventing material loss, rubber beading offers a cost-effective solution for improving the overall efficiency of the screening operation. These advantages collectively make vibrating screen rubber beading an essential and beneficial component in ensuring effective and efficient screening processes across various industrial applications.Vibrating screen rubber beading, also known as screen rubber strip or screen panel sealing strip, is a specialized rubber component used in vibrating screens to provide a tight seal between the screen panels and the frame. Here are its uses and applications: 1. **Screen Panel Sealing**: Vibrating screen rubber beading is primarily used to seal the gaps between individual screen panels and the supporting frame. This sealing ensures that no material leaks or spills around the edges of the screen, maintaining efficiency in the screening process. 2. **Material Classification**: In industries such as mining, aggregate processing, construction, and recycling, vibrating screens are used to classify and separate materials of different sizes. Rubber beading helps ensure that the screening process is precise by preventing undersized or oversized particles from by