Listing ID #3818658

Company Information

Ask for more detail from the seller

Contact Supplier|

PRODUCT DESCRIPTION:

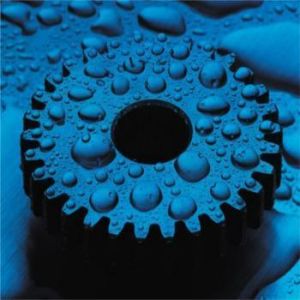

Exports of automotive components are a very critical task which requires specialized Rust Preventive Packaging schemes in synergism with highly effective rust preventive oils. RUSTX-EX Export Grade oils have higher, faster and longer duration of effective chemicals that protect the metallic components from saline atmospheres during sea transportation as well as long-term storage. RUSTX 135 series oils contain VCI chemicals which work in contact phase as well as in the vapour phase and protect components by its dual action. RUSTX - 135 A - Ex rust preventive oil is used where dry to touch feel on the component is required without the need to wash the component before fitting. The thin layered rust preventive also reduces the amount of dust accumulation on the part as well as is an excellent rust preventive for OE supplies where assembly line use of the components is required. |

|

APPLICATION METHOD:

Dipping by far is the best method for establishing an even layer on the component. Other methods may be used such as spraying, Brushing, Automatic Conveyor & Spray Jet provided the complete surface of the component is coated with the rust preventive oil. 135 A – Ex should be used with VCI packaging for best long term corrosion prevention results. Use of gloves while handling the components as well as immediate packaging is important. In case the components carry cutting oils or water from previous processes, dewatering with CL005 is recommended. |

|

FEATURES:

• Dry to touch • Good coverage due to low viscosity-high floatability & high penetration properties • Less consumption due to thin film • Quick Drying - Dries within 5-6 minutes • Doesn’t contaminate cutting fluids • Excellent protection against acidic and saline environments • Excellent Dewatering & Degreasing Properties • Finger Print Remover • Doesn’t produce fumes during welding or heat treatment • Non Sticky washable film PACKAGING AVAILABLE: 26 Liters Can & 210 Liters Barrel SAFETY INFORMATION: RUST-X Rust Preventive Oils donot contain Lead (Pb), Mercury (Hg), Cadmium (Cd), Hexavalent Chromium (Cr6), Polybrominated biphenyls (PBB), or Polybrominateddi-phenylether complying with the re-stricted substances listed in Article 4(1) of the RoHS Directive. RUST-X Rust Preventive Oils are also REACH Compliant for exports to the European Union. This Data sheet and information it contains is considered to be accurate at the date of printing. No representation or warranty, expressed or implied is made as to the accuracy or completeness of the data and information contained in this publication. It is the User’s obligation to evaluate and use products safely and within the scope advised in the data sheet and to comply with all applicable laws and regulations |

| Physical Properties | Test Method | Value |

| Color | Visual | Amber Clear |

| Viscosity @ cSt @ 40°C | ASTM D 445 | 2-3cSt |

| Specific Gravity | ASTM D 1298 | 0.78 - 0.83 |

| Dry Film Thickness | IS 2074 | 1 micron |

| Flash Point (before application) | ASTM D 92 | 70oC |

| Flash Point (after application) | ASTM D 92 | 220 oC |

| Volatiles by % (by weight) | 80% | |

| Coverage (sq m/ Lt) | 200 | |

| Pour Point | ASTM D 97 | Below -5 oC |

| Saponification Value (mg KOH/gm) | ASTM D 94 | 5.0-7.0 |

| Water Displacement Test | Passes | |

| Degreasability | Passes | |

| Drying Time | 10 mins |

| Corrosion Prevention Properties | ||

| Salt Spray with VCI packaging | ASTM B 117 | 500 hours |

| Salt Spray | ASTM B 117 | < 48 hours |

| Humidity Chamber Test | ASTM D 1748 | < 720 hours |

| Indoor Protection Life (open) | 2 months | |

| Indoor protection life (packed) | 2 years | |

| Packaged Protection Life (In VCI Packaging) | Upto 5 years |