Listing ID #4001134

Company Information

Ask for more detail from the seller

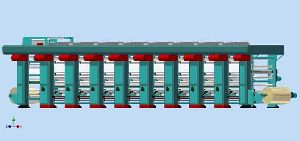

Contact SupplierThe printing machines that are used here come with all kinds of advancements in its system making it a trustworthy equipment over the years. Designed with great advancements, yet they are very user friendly resulting in consistency. The parts of this machine are designed in a way to deliver optimum productivity and moreover maintaining accuracy over a long dependable life.

The MSC-HS is a trolley-type press featuring a solid press frame designed for high speed performance.The shafted configuration enables the press to use either conventional integral cylinders or cylinder sleeves. The press design enables fast make-ready operations and quick changeovers of the entire inking system and the gravure cylinder or, alternatively, only the gravure cylinder.

The doctor blade is fully adjustable. Replacement of the doctor blade holder or only the doctor blade without the use of tools via a quick release mechanism. Fully automatic trolley changeover and fast set-up operation. The trolley can be stainless steel or teflon-coated. A dedicated trolley is available for seal coating. The inking system has been designed for consistent and uniform inking at high speed, as well as low volume of ink in circulation throughout the press.

Modular and highly efficient drying system and ventilation. Single or double length dryers are available to provide the most appropriate system to meet specific production requirements. In addition to conventional heating systems, it is possible to use hot water as the energy source if the temperature range is compatible and recovered thermal energy is available. The book-type opening of the hoods allows optimum access to the dryers for web threading, cleaning and maintenance of rollers and air nozzles.

The printing press features a highly advanced press automation content. The SIEMENS basedcolour touchscreen provides full parameter recipe saving and recorder for quality tracking. All auxiliary equipment process data are integrated in single recipes for consistent job repeatability.

The press can be equipped with either shaftedorshaftless duplex winders. Automatic splice operations can be performed at maximum production speed. The efficient technical solutions that optimize the use and recovery of electrical power enable an important reduction in the level of energy consumption.

Five drive servo driven automatic web tension control systems : Load cell and or dancer based closed loop Servo motor control & drive on (1) Unwind (2) In-feed System (3) Printing Station (4) Out -feed System (5) Rewind.

Master operator control panel mainly consists of touch screen operator interface located at rewind side and also at unwind side, facilitates easy operation from both the end. Electro-electric Edge Guiding System with Ultrasonic edge sensor and PMDC motor is most efficient for web liner application.

Distinctively designed and precisely machined, strong and sturdy, steel frame structure completely machined on CNC-VMC, maintains accuracy over long dependable life and ensures less vibration with 45mm thickness even with optimum line speed.

Pneumatic Ink pump on each station with ink flow/pressure adjusting valve

Motorized web video inspection system consists of high quality CCD color camera, Industrial PC & Monitor (facilitates sequential inspection of the lateral and entire print repeat of the web).

Automatic Register Control System

Automatic length and side-lay register control system with full colored touch screen operator interface facilitates automatic mark centering and recognition. Automatic selection of different control parameters during machine speed changes and control parameters individually configurable to different materials for easy operator selection.

Turret system with flying splice facilitates automatic reel change-over without stopping the machine.The whole function is controlled and supervised by the high performance PLC/PPC.

The system mainly composed of push button initiated motorized rotating disc, pneumatically loaded automatic splicing arm, PU covered pasting roller and cutting blade assembly etc

Pneumatically expanded shafts and safety chucks to hold the reels

- Shaft less System for Unwinder and Rewinder.

- Low friction ball screw compatible with auto register control system.

- Rubber Roll Impression system with linear guide ways.