Listing ID #3920828

Company Information

Ask for more detail from the seller

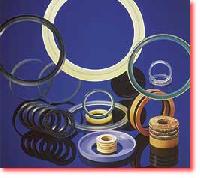

Contact Supplier“DIPTI” DRR series Rotating Rubber Rings are the part of Barge Bumpers, which absorbs and dissipates berthing energy while rotating on to the Contact Post of Barge Bumpers. Its rotating movement reduces Shear force to be exerted by rubbing of Barges / Boats while berthing. They find extensive application in different configuration & Barge Bumper Assemblies. “DIPTI” Rotating Rubber Rings are versatile and can be used for different functions & specifications depending upon exact duty and working conditions. Our “DIPTI” DRR series Rotating Rubber Rings are available in 3 different models as shown here. These rings can also be supplied from high abrasive resistant polyurethane rubber.