Company Information

Ask for more detail from the seller

Contact SupplierUses

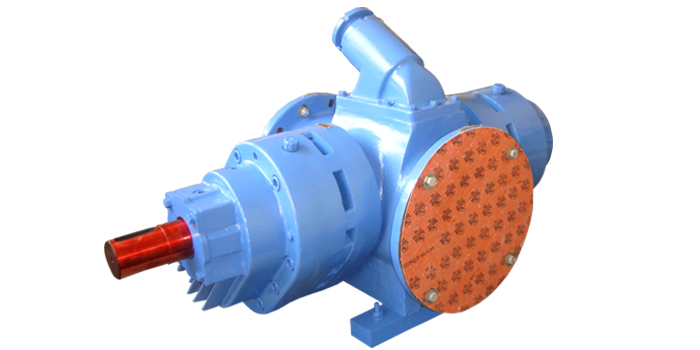

NDX series pumps are designed to handle bulk volume of viscous & semi viscous liquids quite efficiently at medium pressure up to 11 bar. The pump can be coupled directly with drive as impeller speed reduction ismade possible within pump, making it very compact & cost economical & there by reducing the over all cost & space, the timing gear reduces the noise level & enhances the working life of the pump.This pump out performance twin Screw pump in all aspect in this range & they are suitable for wagon decanting, cargo-un-loading of various viscous liquids such as edible oils, Fuel oils, viscous chemicals etc. Step-down Versions are also available; type MDX comes without reduction gears where as type JDX comes without timing & reduction gears, type JDB is with bush bearing suitable for molasses applications.

MOC

| 01 | Pump Body | 1 | C.I.Gr.-20/CS | 08 | Impeller Gears | 4 | EN-8 BS 970 | 15 | Bush Bearing | 1 | Bronze |

| 02 | Front Cover | 1 | C.I.Gr.-20 IS 210 | 09 | Wearing Plate | 4 | LT - Bronze | 16 | R.V. Body | 1 | C.I.Gr.-20/CS |

| 03 | Back Cover | 1 | C.I.Gr. -20 IS 210 | 10 | Needle Roller Brg. | 8 | IKO-INA | 17 | Relief Valve Piston | 1 | En-8 BS 970 |

| 04 | Oil Seal Cover | 1 | C.I.Gr. -20 IS 210 | 11 | "V" Seal/Me. Seal | 8 | Viton/Burg. | 18 | Spring | 1 | Spring Steel |

| 05 | Bearing Cover | 2 | C.I.Gr.-20 IS 210 | 12 | R.H. & L.H. Timing Gear | 1+1 | EN-353 H & G BS 970 | 19 | R.V. AD Screw | 1 | En-8 BS 970 |

| 06 | Rotor Shaft | 1 | EN-9 H & G BS 970 | 13 | Pinion & Reduction gear | 1+1 | EN-353 H & G BS 970 | 20 | Flushing Wheel | 1 | En-8 BS 970 |

| 07 | Stator Shaft | 1 | EN-9 H & G BS 970 | 14 | Pinion Supp. Ball Brg. | 2 | SKF | 21 | Washer | 3 | En-8 BS 970 |

Pump Model - Size - Capacity & Dimensions

| Pump Model & Size | Designed Capacity at 960. RPM Qd M3/hr | Coefficient of | Impeller Size | Weight of Bare Pump in KG | |||

|---|---|---|---|---|---|---|---|

| Slippage Cs | Viscouse Power Cv | Dia | F/W | ||||

| NDX-500 5" X 5" | S | 80.00 | 15.35 | 10.50 | 114 | 226 | 200 |

| L | 95.00 | 15.35 | 12.50 | 280 | |||

| NDX-600 6" X 6" | S | 125.00 | 20.50 | 13.95 | 136 | 226 | 265 |

| L | 175.00 | 20.50 | 15.65 | 320 | |||

| NDX-800 8" X 8" | S | 200.00 | 25.40 | 18.50 | 160 | 276 | 325 |

| L | 275.00 | 25.40 | 20.25 | 380 | |||

| NDX-1000 10" X 10" | S | 325.00 | 33.50 | 22.50 | 193 | 316 | 410 |

| L | 425.00 | 33.50 | 25.50 | 410 | |||

| NDX-1200 12" X 12" | S | 475.00 | 40.20 | 33.50 | 218 | 400 | 550 |

| L | 550.00 | 41.25 | 35.75 | 450 | |||

Dimension

| Model | Pump Dimensions | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Overall | Mounting & Shaft | Flange | |||||||||

| A F | H3 H4 | B C | E T | L L1 | H1 H2 | ØD | P Q | D2 D3 | D4 K | ||

| NDX-500 5" X 5" | S | 720 | 510 335 | 200 | 380 | 75 | 215 | 47 | 16 | 254 | 216 |

| L | 435 | 200 | 36 | 80 | 182 | 51.5 | 22 | 08 | |||

| NDX-600 6" X 6" | S | 810 | 565 400 | 250 | 385 | 93 | 260 | 57 | 16 | 279 | 241 |

| L | 512 | 250 | 35 | 105 | 221 | 61.5 | 22 | 08 | |||

| NDX-800 8" X 8" | S | 970 | 640 450 | 300 | 450 | 85 | 292 | 74 | 20 | 340 | 292 |

| L | 560 | 300 | 42 | 90 | 245 | 79 | 22 | 08 | |||

| NDX-1000 10" X 10" | S | 1075 | 720 500 | 350 | 465 | 90 | 320 | 77 | 22 | 406 | 362 |

| L | 610 | 350 | 50 | 100 | 275 | 84.5 | 25 | 12 | |||

| NDX-1200 12" X 12" | S | 1200 | 825 575 | 400 | 625 | 100 | 375 | 85 | 22 | 482 | 432 |

| L | 700 | 400 | 50 | 120 | 310 | 91 | 25 | 12 | |||

Flow and Power Calculation

| Qa(actual) = (Pump RPM/960)Qd - Qs(Sleepage flow) where Qs=Cs X Cd X Ci | Pa(actual) = Pump RPM/960 X (Qd X ∆P)27 + Pv(Viscous power) Where Pv=Cr X Cv X Cp | ||||||||||||||||

| Coefficient of Differential Pressure(Cd) | Coefficient of leakage & extra power for different viscosity | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ∆P Kg/Cm2 | 2 | 4 | 5 | 7 | 9 | 10 | 12 | Viscosity CST | 1 | 10 | 35 | 75 | 150 | 350 | 600 | 850 | 1250 |

| Coeffi. ∆P | 0.35 | 0.55 | 0.65 | 0.80 | 0.92 | 1.00 | 1.10 | Coeffi Leakage Ci | 2.75 | 2.00 | 1.50 | 1.20 | 1.00 | 0.85 | 0.70 | 0.65 | 0.60 |

| Coeffi Ex.Power Cp | 0.40 | 0.55 | 0.75 | 1.00 | 1.25 | 1.85 | 2.25 | 0.65 | 3.25 | ||||||||

| Reduction ratio & available Pump RPM when coupled with 1440 RPM prim-mover(to be corrected to actual speed) | |||||||||||||||||

| Reduction Ratio | 1:2.2 | 1:2.1 | 1:2 | 1:1.9 | 1:1.8 | 1:1.7 | 1:1.6 | 1:1.5 | 1:1.4 | 1:1.3 | 1:1.2 | 1:1.1 | |||||

| Pump RPM | 655 | 686 | 720 | 758 | 800 | 847 | 900 | 960 | 1028 | 1108 | 1200 | 1309 | |||||

| Coefficient RPM Cr | 0.27 | 0.29 | 0.32 | 0.35 | 0.37 | 0.4 | 0.45 | 0.49 | 0.52 | 0.62 | 0.72 | 0.82 | |||||