Listing ID #3535773

Company Information

Ask for more detail from the seller

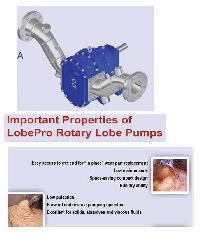

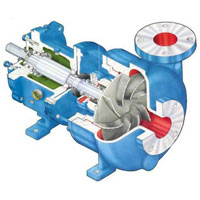

Contact SupplierRotary lobe pump use timing gears to eliminate contact between the rotors, which allows their use on non-lubricating fluids. These pumps offer low shear and gentle handling of the liquid to minimize product degradation. Rotary lobe pumps are useful for pumping and Transfer of all high viscous liquids like syrup paints, drugs, food products, etc.

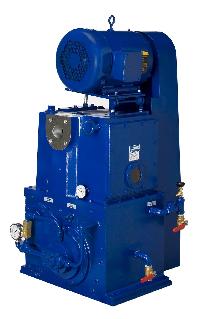

Lobe pump is used in a variety of industries including, pulp and paper, chemical, food, beverage, pharmaceutical, and biotechnology. They are popular in these diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics.

| Features (Rotary Lobe Pumps) | |||||||||||||||||||

|

|||||||||||||||||||

|

Working for Lobe Pump

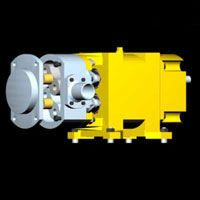

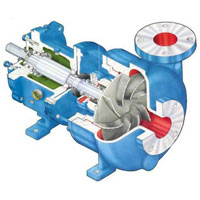

Lobe pump are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timing gears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection.

|

|||||||||||||||||||

| Application (Rotary Lobe Pumps) | |||||||||||||||||||

|

| PUMP Model | Port Size | Displacement @100 rpm |

|

| LPM | US. GPM |

||

| ALB 100S | 1" | 5 | 1.4 |

| ALB 100L | 1" | 8 | 2.25 |

| ALB 150S | 1 1/2" | 12 | 3.38 |

| ALB 150L | 1 1/2" | 18 | 4.78 |

| ALB 200S | 2" | 26 | 7.03 |

| ALB 200L | 2" | 38 | 10.15 |

| ALB 250S | 2 1/2" | 55 | 14.64 |

| ALB 250L | 2 1/2" | 79 | 20.87 |

| ALB 300S | 3" | 116 | 30.65 |

| ALB 300L | 3" | 168 | 44.39 |

| ALB 400S | 4" | 261 | 68.70 |

| ALB 400L | 4" | 354 | 93.26 |