Listing ID #4736951

Company Information

Ask for more detail from the seller

Contact SupplierApart from plates and paste of lead oxide from scrap batteries, slag from Mini Blast Furnace is charged in the Rotary Furnace.

In addition to these, certain compounds of sulphur are also present in the batteries. When this material is heated in thePresence of carbon, lead oxide is converted to lead. This conversion along with burning of fuel generates flue gases and fumescontaining dust, dirt, oxides of lead, lead particles and such other impurities etc.

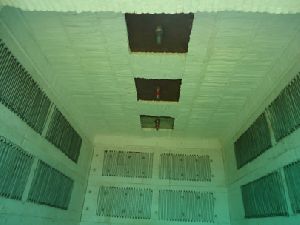

Hence, to meet various goals of maintaining employees' health and factory environments as well as regulatory requirements,it becomes imperative to get high end Air Pollution Control Systems to be installed with the Rotary Furnaces.