Company Information

Ask for more detail from the seller

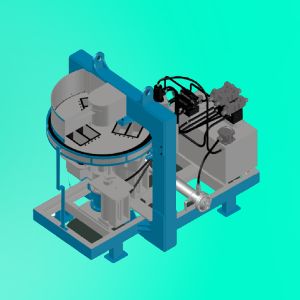

Contact SupplierWe offer high efficiency Rotary Forging Machine that is highly appreciated in the markets. Our Precision Rotary Forging Machine is designed as per the national and international quality standards. Manufactured from the advanced technology parts, our Precision Rotary Forging Machine is highly functional and easy to operate. Providing long lasting performance, our Precision Rotary Forging Machine needs low maintenance cost. We have firmly positioned ourselves as one of the prime CNC Rotary Forging Machine Suppliers based in India.

What is Rotary Forging?