Listing ID #5562727

Company Information

Ask for more detail from the seller

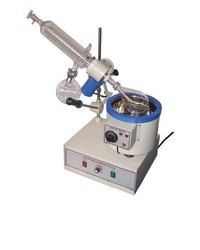

Contact SupplierAblaze is a leading Rotary Evaporator Manufacturer and Supplier, we offer a large capacity commercial rotary vaccum evaporator. The Ablaze Rotary Evaporator system operates under conditions of vacuum or atmosphere.

The most common form in research is the 1 Liter to 5 Liter bench-top model, whereas, in industrial chemical operations, large-scale rotary evaporator (10L to 20 Liter and 50 Liter, 100 Liter to 200 Liter) models are used in pilot plants.

Ablaze’s series of Rotary film Evaporators are designed for Pilot and industrial scale evaporation applications.

Exclusive use of superior quality Borosilicate 3.3 glass and PTFE for all components coming in contact with product ensures complete chemical resistance against almost all mediums. It is primarily used for distillation of heat sensitive and volatile components, owing to its unique construction. It can operate under full vacuum and is an essential equipment in the chemical and pharmaceutical industries.

Salient Features of Rotary Evaporator :

Rotary Evaporator Manufacturer & Supplier

The rotary evaporator (rotavaps) is an instrument for an active and mild extraction of solvents by evaporation in chemical, pharmaceutical, cosmetics, herbal extraction and fragrances, and laboratories.

Rotary vaccum evaporators are also used for the chemical processing of distillates and extracts. The use of borosilicate and PTFE allows aggressive materials to be handled satisfies all application needs. Explore the wide variety of industrial and R&D rotary evaporators. Completely safe instruments and the best optimization of efficiency.

Ablaze manufacture and supply a variety of rotary film evaporator capacities of 5 liters, 10 liters, 20 liters, 50 liters, 100 liters, 200 liters, GMP Model & Non-GMP Model, including electrical ATEX/Non-flame proof/touch screen display or as needed by the customer.

Rotary Evaporator Working Concept

The most rapid, reliable and environmentally safe method of extracting a volatile solvent from a non-volatile sample is to provide a rotary evaporator. For a modern chemical laboratory, this is normal equipment used to evaporate the solvent under vacuum with the use of rotation and heat.

The theory of the rotary evaporator is that the boiling points of the liquids decrease their pressure, allowing solvents to be vaporized at much lower temperatures at normal pressure than their boiling points. A vacuum system is required to complete the entire procedure, selecting an appropriate vacuum pump for your rotavap will effectively improve the efficiency of the evaporation.

At the other end, a condenser converts gas into a liquid, and lower temperatures are required. Dry ice, water or liquid nitrogen were always used to achieve a cooling effect. The evaporation vessel rotates continuously. This technique is intended to increase the fluid surface area. The centrifugal force prevents the liquid from sticking to the vessel’s inner surface, creating a larger surface area and causing faster evaporation.

Once all the solvent evaporated (or whatever is desired at this point), the vacuum is released. The rotary flask is removed from the bath and the rotation is stopped. The vacuum is used to lower the boiling temperature thus minimizing the damage to the thermolabile substance.

Rotary Evaporator Applications :

Why Buy Rotary Evaporator from Ablaze?

Related Rotary Evaporator Glassware can be customized to meet the specific needs of the Client.

Get the best rotary film evaporator performance at a reasonable cost.

We also have a professional technology team to help clients with problems related to their system (rotary evaporator).

Our technical experts are always available, by phone, e-mail or live chat, to help customers with specific questions about the operation and maintenance of rotary evaporators.

| DESCRIPTION | ARE 10 | ARE 20 | ARE 30 | ARE 50 | ARE 100 | ARE 200 |

|---|---|---|---|---|---|---|

| Evaporation Flask-Capacity | 10L | 20L | 30L | 50L | 100L | 200L |

| Heater | 4kW | 4kW | 6kW | 10kW | 12kw | 12kW |

| Bath Lift | Electrically Controlled | |||||

| Rotation Speed | 0-90 rpm | 0-90 rpm | 0-90 rpm | 0-90 rpm | 0-50 rpm | 0-50 rpm |

| RPM Indicator | Digital Display | |||||

| RPM Control | Controlled through Panel (VFD) | |||||

| Temperature Range (Heating Bath) | Digital: 20-90°C (water bath) / Digital: 20-180°C (oil bath) | |||||

| Temperature Control | PID controlled from the main heater | |||||

| Overheat Cut-Off Protection | Yes | |||||

| Ultimate Vacuum | 1 Torr | 1 Torr | 1 Torr | 1 Torr | 3 Torr | 5 Torr |

| Receiving Flask-Capacity | 10 ltr. | 10 ltr. | 20 ltr. | 20 ltr. | 30 ltr. | 50 ltr. |

| Condenser Area | > 0.5 m² | > 0.5 m² | > 1.0 m² | > 1.5 m² | > 2.5 m² | > 4 m² |

| Power Source | AC 230V / 3Phase / 50 Hz | |||||

Ablaze Export Pvt. Ltd. is a well-known organization from Vadodara (Gujarat) that is instrumental in offering the finest range of industrials products. We serve as a dependable manufacturer, exporter and supplier of Distillation Units, Evaporators, Glass Reactors, Acid Concentration Plant, Dry HCL Gas Generator, Bromine Recovery Plant, Gas Absorber, Glass Pressure Relief Valve, Glass Coil Condenser, Mobile GAS Scrubber, Sulfuric Acid Dilution Plant, Easy Reactor Lifting System, Heating & Cooling Circulator, Glass Nutsche Filter, Glass Mixer Settler, and Glass Shell & Tube Heat Exchanger. We are also involved in handling turnkey projects for such offerings. These products are manufactured using the finest components and parts, which allow us in making available precision engineered products. Our distribution network is well-knit across all major global regions due to which we ship products safely and timely.

Ablaze Export Pvt. Ltd. is a prominent name in its area of operation. The company is based in Vadodara (Gujarat) and our Managing Director Mr. Rohit Gupta leads company’s business operations in the regional and international marketplaces. With years of industry knowledge and market exposure, he founded the company in the year 2010. We operate in the global market and serve the industrial demands with perfection and commitment.

Infrastructure

The company boasts of a sound infrastructural facility that is spread over sprawling area of land. Our facility comprises of modernistic equipment, design unit, and in-house quality testing facility, which help us ascertain products that conform to the highest standards of quality are shipped to buyer destinations.

Vendor Selection

We are a quality-conscious organization that selects vendors carefully in order to get the best quality materials for production. Following are the parameters on which we select our vendors: