Listing ID #3844766

Company Information

Ask for more detail from the seller

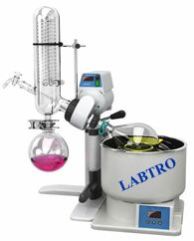

Contact SupplierA rotary evaporator is a device used in Chemical Laboratories for efficient and gentle removal of solvents from samples by evaporation.

The main components of a rotary evaporators are:

The vacuum evaporators as a class function because lowering the pressure lowers the Boiling Points of component liquids in it. Generally, the component liquids of interest in applications of rotary evaporation are solvents that one desires to remove from a sample after an extraction, for instance, following a natural product isolation or a step in an organic synthesis. Use of a Rotary Evaporator, therefore allows liquid solvents to be removed without excessive heating of what are often complex and sensitive solvent – solute combinations.

Advantages of Rotary Evaporators