Listing ID #4719671

Company Information

Ask for more detail from the seller

Contact SupplierFor all the people involved with maintenance of battery units in a factory, the rope handle with grips is a very useful battery accessory. The rope handles manufactured by JK Ceraplast a market leader in battery vent caps and Battery Accessories is much sought after. These handles with rope are most suited for repeated maneuvers as they are pliable and make the job of lifting heavy battery definitely easier.

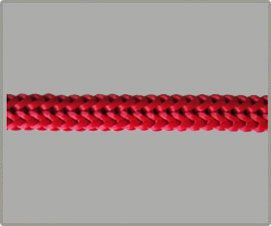

The ropes have a very sturdy construction as they are created by twining polypropylene layers which together has amazing tensile strength. This rope battery handles have an additional built-in grip that provides a much easier holding as there are finger indents designed into them. Having rope handles with comfortable grips makes the work load of the maintenance staff easy and ensures there is no damage to battery when it is being shifted.