Listing ID #4420463

Company Information

Ask for more detail from the seller

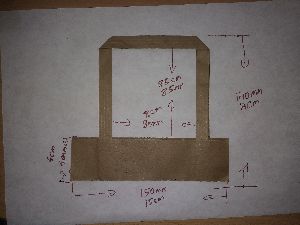

Contact SupplierJK Ceraplast is established as a market leader in manufacture and export of various types of Battery Vent Caps and Battery Accessories. One of the most prominent battery accessory products is the Rope Handles for Batteries. It is often required to move batteries from the charging bay to a storage facility and at times like that an easy way of moving batteries to and fro is essential. For such use it is common to use a makeshift battery handle and the Battery handle with Rope is most popular in this segment.

These Rope Handles are made with top grade Polypropylene which is twisted to create a very strong woven rope. This style of battery handle is ideally suitable for use with N 100 to IT 500 batteries. The exceptional quality of rope battery handles made by JK Ceraplast has been certified by an external agency to comfortably lift a weight of around 70 kilos. This ensures completely safety for the maintenance staff and there is no danger from a weak rope in such types of handles.