Listing ID #3956310

Company Information

Ask for more detail from the seller

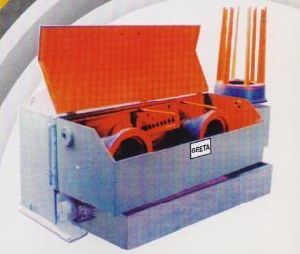

Contact SupplierZenith Rod break down machines are used to draw non-ferrous wire rods.

Zenith machinery are noted for their durability and productivity. Numerous machines are in regular use around the globe,

This machine was specifically designed for high speed production of wire where floor space is limited. The Zenith step cone type rbd is supplied with 4 three step drawing capstans, a finishing capstan and 13 die positions as standard. The use of AC inverter will give a wider finishing speeds. Drafting is at a constant 20.6%.

The machine is constructed of a rigid fabricated housing comprising of four Drawing capstan shafts. The drawing capstan is supplied with three diameter steps. All pull-blocks including the capstan shaft assembly are completely enclosed. All dies are located inside the machine and spray lubrication of the wire and drawing capstan is employed, the dies being lubricated by jets at entry and exit.

This is a product between Step cone type and tandem type rod break down machine.

The Zenith step cone type rbd is supplied with 6 two step drawing capstans, a finishing capstan and 13 die positions as standard.

The use of AC inverter will give a wider finishing speeds. Drafting is at a constant 20.6%.

The machine can also be supplied in configuration of 9Die and 11Die.

Modular design enables this machine to be supplied with 7, 10, 13 or 16 dies, dependent on the required duty. . The drawing capstans can be fitted with replaceable HCHCR or Tungsten Carbide coated rings.

Tandem type machines are ideal for the drawing of high quality copper, aluminium and aluminium alloy.

The drawing and the finishing capstan have a diameter of 450mm.Each drawing capstan is offset progressively along the wire line to provide a nearly straight wire entry into each die.

Die holders are fully adjustable to the natural arc of the wire. The finishing die holder is of the motorised revolving type. Facilities for driving a Drive arrangement for continuous annealer are provided at the rear of the capstan shaft.

The motor is positioned behind the machine and is connected by flexible couplings to an internal gearbox.

Spray lubrication of the die holder and drawing capstan is employed on this machine. Dies are being lubricated by jets at entry and exit. Feed and drain connections are provided for connection to a lubricant storage system (which is not supplied).

Standard equipment includes an inching pedal stretching the length of the machine and a broken wire switch.

The Trolley Rod Breakdown machine is available with 5/ 6 die positions for the production of railway contact wire. The machine is versatile with die provision for a grooved attachment at the fifth and sixth die position to impart groove in the conductor. The drawing capstans are driven by individual gearboxes connected to the main drive motors.

Drafting can be changed to suit round or trolley wire sections by changing the relative block speeds.

The drawing capstans are each mounted on a reduction gearbox and the gearboxes are all supported on an individual single rigid baseframe.

The motor and gearbox are mounted separately.

The main machine is enclosed with a steel guard and the access to the drawing capstans is by a front guard.

• Maximum Entry

• 9.5mm aluminium

• 8.0mm copper

• Finish Diameter

• 1.5mm to 4.1mm diameter

• Maximum Finishing Speed

• 25 m.p.s

• Motor power

• 150Hp – 300Hp

Specification Of Double Tandem Type RBD

• Maximum Entry

• 9.5mm aluminium

• 8.0mm copper

• Finish Diameter

• 1.5mm to 4.1mm diameter

• Maximum Finishing Speed

• 25 m.p.s

• Motor power

• 150Hp – 300Hp

| Type | Non-Ferrous Rod Break Down Machine Tandem Type |

Non-Ferrous Rod Break Down Machine Cone Type |

| Model | RBD-7/9/11/13T | RBD - 11/13C |

| Material | Cu./AI. | Cu./AI. |

| Inlet Wires Dia (mm) | 8/9.5 | 8/9.5 |

| Finishes Wire Dia (mm) | 1.6/.2 | 1.6/.2 |

| No. of Dies | 7/9/11/13 | 11/13 |

| No. of Cone Blocks | - | 4 |

| Working reduction % | 20.6 | 20.6 |

| Basic reduction % | 19 | 19 |

| Finishing Speed (m/sec) | 8/10/12 | 6/8 |

| Drive Trans | Gears | Gears |

| Main Drive (k.w.) | 110/180/220 | 110/180 |

|

Control AC/DC/ Inverter |

As Per Specs | As Per Specs |

| Largest Step Dia | 400/300 | 483 |

| Extractor Capstan Dia | 400 | 400 |

| Cone Material | H.C.H.C. | H.C.H.C. |

| Spooler | Ind. Drive | Ind. Drive |

| Bobbin Size mm (din spec) | 500/630 | 500/630 |