Listing ID #3862659

Company Information

Ask for more detail from the seller

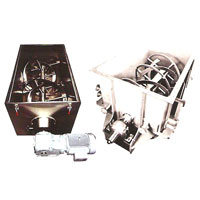

Contact SupplierRibbon Blenders are best suited for mixing, granulation and homogenizing batch process. It handles a range of applications from all types of powders including free flowing to cohesive and moist powders, bulk dry materials to wet cakes and slurries.

|

||||||||||||

| A double helical ribbon agitator in the vessel moves the product upward along the outer wall and releases it downward into cavities developed in the middle, simultaneously material is horizontally distributed by the mixing arm and is optimally homogenized. | ||||||||||||

| Mixing time is depending on the agitator speed. In general mixing time is three to four times shorter than the mixers working with a rotating screw. | ||||||||||||

| The drive and bearings are kept outside of the vessel, no gears or seals in the product compartment. The rotating central agitator shaft does not have bottom bearing support there by eliminating any dead spots or difficult areas to clean and there is no danger of product contamination. Discharge of the product is fast and simple as full bore open. | ||||||||||||

| Design Options : | ||||||||||||

|

||||||||||||