Listing ID #4315268

Company Information

Ask for more detail from the seller

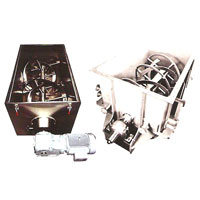

Contact SupplierWe are one of the prominent manufacturers and exporters of Ribbon Blenders in the market. Our range of ribbon blender is manufactured using superior grade raw materials like stainless and mild steel. These ribbon blenders comprise of a stainless steel or mild steel centre shaft fitted with specially designed agitator blades for providing the contra flow action. Further, our ribbon blender is also equipped with a couple of ribbons. The outer ribbon of our range moves the ingredients into the blender and the inner ribbon constantly circulate the material.

|

|