Listing ID #4261761

Company Information

Ask for more detail from the seller

Contact SupplierPrakash is one of the leading manufacturers, suppliers & Exporters of Ribbon Blenders in India.

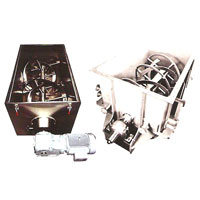

The RIBBON BLENDER is an efficient and versatile blending machine for mixing of dry granules & powders homogeneously. Approximately two third of the volume of the container of Ribbon Blender is filled to ensure proper mixing. The Ribbon Blender gives best result for mixing of dry powder & granules due to the design and shape of the mixing ribbon and product container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc.

|

SPECIAL FEATURES OF RIBBON BLENDER : |

|

Panel provided with following facilities in 500 Liters & bigger model. In Small model only D.O.L. starter provided for On-Off operation of the motor.

|

|

Types of Models :

| Model |

100 |

250 |

500 |

750 |

1000 |

1500 |

2000 |

3000 |

5000 |

|

Gross Cap |

100 |

250 |

500 |

750 |

1000 |

1500 |

2000 |

3000 |

5000 |

|

Working Cap |

80 |

200 |

400 |

600 |

800 |

1200 |

1600 |

2400 |

4000 |