Listing ID #3947353

Company Information

Ask for more detail from the seller

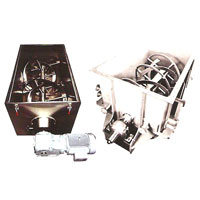

Contact SupplierThe RIBBON BLENDER is an efficient and versatile blending machine for mixing of dry granules & powders homogeneously. Approximate two third of the volume of the container of Ribbon Blender is filled to ensure proper mixing. The Ribbon Blender gives best result for mixing of dry powder & granules due to the design and shape of the mixing ribbon and product container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc.

Material should be charge from the top side. There are port/ports should be provided on the top cover to charge the material as well as for air vent. One discharge valve provided at the bottom side at center of the container. The discharge height could be adjust as per the requirement, so that material gets discharge in the other container directly, so that material handling time for discharge is nil and the operation is dust free.

Ribbon Blender:

In Ribbon Blender the powder moves from center to the end of container and end of container to the center of container. Hence requirement of total mixing time is very less and the RPM required are also very less.

The dry material gets sufficient contineous movement due to the shape & movement of ribbon & shape of the container., which moves material for good quality of blending.

The unit is consist of one electrical motor, one worm reduction gear, belt drive between motor and gear, couple drive between gear to ( ribbon ) mixing stirrer. Container having four nos. of legs with discharge valve & top cover. Both end of mixing shaft is sealed with bush & PTFE gland housing & safety guards are provided on all moving parts.

|

Special Features of the Ribbon Blender:

Contact Us for Your Need of Horizontal Ribbon Blenders, Vertical Ribbon Blenders, Dry Ribbon Blenders, Cylindrical Ribbon Blender, Vacuum Type Ribbon Blender, Pharmaceutical Ribbon Blender, Chemical Ribbon Blender, Ribbon Blender for food Industry, Ribbon Blender for Fertilizers, Conical Ribbon Blenders, Ribbon Blender Mixers, Double Spiral Ribbon Blender, ribbon mixer, stainless steel Ribbon Blender, Spiral Ribbon Mixer, Double Ribbon Blender, Day Ribbon Blender, Vertical Single Shaft Ribbon Blenders, Heavy duty Ribbon Blenders, Portable Ribbon Blenders, etc. Please inquire with Different working capacity in cubic foot / feet, Kg / Kilogram, Liters, size in inch, meters, cm, Width, Height, Length, deep or depth, Thickness, Power in HP, Watt, Voltage, etc. |