Listing ID #4194271

Company Information

Ask for more detail from the seller

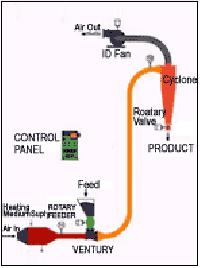

Contact SupplierIn radio frequency drying, material is exposed to an electronic field that alternates about 40,000,000 times per second. When the field alternates, the water molecules in the material also alternate. The resulting friction causes the water to heat uniformly throughout the product. Radio frequency drying can save energy because only the product itself is heated. Another benefit is that no equipment warm up or cool down is necessary. The technology typically replaces process steam heat.

The RF Web Dryer rapidly removes moisture from the web at low temperatures and prevents the migration of coating solids caused by conventional drying which increases web strength and product quality.

Benefits

Features

Barriers to Market Acceptance

Applications

Radio frequency drying is often used to dry crackers, cookies, and other snack foods after they've been baked. It can also be used to dry ceramics, synthetic foam, textiles, water-based inks and adhesives in paper products, and fiberglass yarn. Other applications include sterilizing bagged materials and preheating thermoset plastic molding compounds. Drying municipal sludge and timber is being investigated.