Listing ID #4171343

Company Information

Ask for more detail from the seller

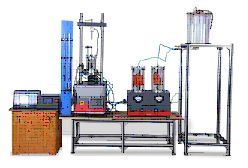

Contact SupplierThe Reichert tester is an excellent tool for lubricant and additive manufacturers to evaluate the wear preventive (WP) and extreme pressure (EP) properties of their samples. This test was developed as a quick method to identify the formation of a lubricating film between two test surfaces. The Reichert Tester uses a drop in noise level (screeching) to identify when a lubricating film is successfully formed between the test surfaces.

Traditionally, this tester was shut off when a perceivable reduction in noise was observed. This required trained and an experienced operators to run tests with accuracy. As a result of this operator dependency there was often a variance in the observed test results. This problem was addressed by Ducom by incorporating instrumentation to monitor and log noise level, therefore reducing operator dependency.

The Reichert Tester sees significant utilization by lubricant and additive manufacturers to evaluate and rank their products quickly in their development / product formulation phase. It is also very useful for additive depletion studies and lubricant selection for metallurgy. This tester also sees use as an effective tool to determine lubricant quality while in use in machinery. Its requirement for a small sample volume allows maintenance staff to withdraw small lubricant samples from machinery and run a quick test to determine if it is time to replace the lubricant. This tester is capable of testing both, lubricating oils and greases.