Listing ID #4293261

Company Information

Ask for more detail from the seller

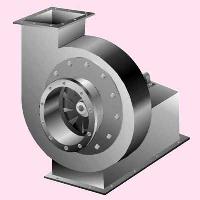

Contact SupplierRegenerative Blowers for High volume Vacuum or Compressed Air Application. Air Flow Capabilities range from 80 to 2050 m3/h , Vacuum capabilites up to -80 to -730 mbar at 50HZ & Pressure CapabIlities Up to 80 to 1040mbar at 50HZ. Single & Double stage models avaliable.

Requiring no lubrication and virtually no maintenance, Regenerative Blowers for high volume vacuum or compressed air applications offers both motor-mounted and separate drive models.

The Regenerative Principle

In a regenerative blower the compression space consists of a hollow circuilar ring between the tips of the impeller blades and the walls of the housing . in operation the rotating impller draws in air from the inlet port into the compression space and moves it radially outwards to the curved housing by centrifugal farce. The action is called regenerative because a certain amount of air slips past each impeller blade during rotation and returns to the base of a succeeding blade for reacceleration.

Because of this dynamic principle regerenrative blowers can generate pressure & vacuum permormance comparable to many multi-satge or positive displacement blowers.

Product Features

| Product Model | Rated Power(Kw) | Max.Flow(m3/h) | Max.Vacuum(mbr) | Max.Pressure(mbr) |

|---|---|---|---|---|

| 2RB 010 H06 | 0.2 | 40 | -60 | 70 |

| 2RB 110 H06 | 0.25 | 55 | -80 | 80 |

| 2RB 210 H06 | 0.25 | 80 | -100 | 110 |

| 2RB 210 H16 | 0.4 | 80 | -120 | 130 |

| 2RB 230 H06 | 0.25 | 105 | -70 | 80 |

| 2RB 230 H16 | 0.4 | 105 | -120 | 130 |

| 2RB 230 H26 | 0.7 | 105 | -120 | 130 |

| 2RB 310 H06 | 0.55 | 100 | -120 | 130 |

| 2RB 310 H16 | 0.7 | 100 | -150 | 170 |

| 2RB 330 H06 | 0.55 | 140 | -60 | 60 |

| 2RB 330 H16 | 0.75 | 140 | -100 | 100 |

| 2RB 490 H16 | 0.6 | 140 | -120 | 120 |

| 2RB 410 H06 | 0.7 | 145 | -120 | 120 |

| 2RB 410 H16 | 0.85 | 145 | -160 | 160 |

| 2RB 410 H26 | 1.3 | 145 | -170 | 200 |

| 2RB 430 H06 | 0.7 | 180 | -70 | 70 |

| 2RB 430 H16 | 0.85 | 180 | -120 | 120 |

| 2RB 430 H26 | 1.3 | 180 | -170 | 220 |

| 2RB 590 H26 | 1.1 | 210 | -130 | 150 |

| 2RB 510 H06 | 0.85 | 210 | -110 | 100 |

| 2RB 510 H16 | 1.3 | 210 | -170 | 170 |

| 2RB 510 H26 | 1.6 | 210 | -200 | 190 |

| 2RB 510 H36 | 2.2 | 210 | -220 | 270 |

| 2RB 530 H06 | 0.85 | 270 | -40 | 40 |

| 2RB 530 H16 | 1.3 | 270 | -100 | 100 |

| 2RB 530 H26 | 1.6 | 270 | -100 | 150 |

| 2RB 530 H36 | 2.2 | 270 | -150 | 230 |

| 2RB 610 H06 | 1.6 | 270 | 180 | 190 |

| 2RB 610 H16 | 2.2 | 270 | -230 | 250 |

| 2RB 610 H26 | 3 | 270 | -270 | 310 |

| 2RB 630 H06 | 1.6 | 345 | -125 | 125 |

| 2RB 630 H16 | 2.2 | 345 | -200 | 195 |

| 2RB 630 H26 | 3 | 345 | -240 | 220 |

| 2RB 710 H06 | 1.6 | 318 | -160 | 150 |

| 2RB 710 H16 | 2.2 | 318 | -210 | 200 |

| 2RB 710 H26 | 3 | 318 | -270 | 290 |

| 2RB 710 H37 | 4 | 318 | -290 | 330 |

| 2RB 730 H06 | 1.6 | 420 | -100 | 100 |

| 2RB 730 H16 | 2.2 | 420 | -170 | 170 |

| 2RB 730 H26 | 3 | 420 | -220 | 220 |

| 2RB 730 H37 | 4 | 420 | -260 | 310 |

| 2RB 740 H57 | 7.5 | 500 | -240 | 320 |

| 2RB 790 H26 | 2.2 | 320 | -160 | 200 |

| 2RB 810 H07 | 4.3 | 530 | -200 | 200 |

| 2RB 810 H17 | 5.5 | 530 | -300 | 320 |

| 2RB 810 H27 | 7.5 | 530 | -320 | 380 |

| 2RB 830 H07 | 4 | 700 | -150 | 140 |

| 2RB 830 H17 | 5.5 | 700 | -200 | 180 |

| 2RB 830 H27 | 7.5 | 700 | -270 | 260 |

| 2RB 910 H07 | 8.5 | 1050 | -210 | 210 |

| 2RB 910 H17 | 12.5 | 1050 | -280 | 270 |

| 2RB 910 H37 | 18.5 | 1050 | -340 | 460 |

| 2RB 930 H07 | 8.5 | 1370 | -120 | 110 |

| 2RB 930 H17 | 12.5 | 1370 | -210 | 190 |

| 2RB 930 H37 | 18.5 | 1370 | -310 | 320 |

| 2RB 010 A01 | 0.2 | 40 | -60 | 70 |

| 2RB 110 A01 | 0.25 | 55 | -80 | 80 |

| 2RB 210 A01 | 0.25 | 80 | -100 | 110 |

| 2RB 210 A11 | 0.4 | 80 | -120 | 130 |

| 2RB 230 A11 | 0.4 | 80 | -120 | 130 |

| 2RB 310 A01 | 0.55 | 95 | -120 | 130 |

| 2RB 310 A11 | 0.7 | 100 | -150 | 170 |

| 2RB 330 A21 | 0.75 | 95 | -100 | 120 |

| 2RB 410 A01 | 0.7 | 145 | -120 | 120 |

| 2RB 410 A11 | 0.85 | 145 | -160 | 160 |

| 2RB 410 A21 | 1.3 | 145 | -170 | 200 |

| 2RB 430 A11 | 0.85 | 180 | -100 | 110 |

| 2RB 430 A21 | 1.3 | 145 | -170 | 200 |

| 2RB 510 A01 | 1.3 | 210 | -170 | 170 |

| 2RB 510 A11 | 1.5 | 210 | -200 | 190 |

| 2RB 530 A01 | 1.3 | 210 | -170 | 170 |

| 2RB 530 A11 | 1.5 | 210 | -200 | 190 |