Listing ID #3814361

Company Information

Ask for more detail from the seller

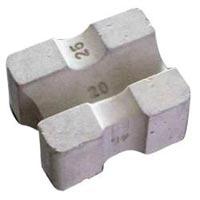

Contact Supplierwe manufacture refractory bed material using high quality raw material that gives high performance, long lasting life. refractory. bed materials are the most opt and essential materials with high strength and no-fusion used in high temperature boilers and furnaces in various industries. the refractory bed materials will attain more quality by its constitute composition they are classified. we use modern technology to provide our customers with the best in the industry.

types of refractory bed materials we manufacture:

i.s. -6 quality refractory bed materials

is-6 - we manufacture this finest bed material which is prepared using modern technology and satisfies all the requirement of the customers. the quality of the bed material is upto 30% alumina.

i.s. -8 quality refractory bed materials

this material has a quality of 40% alumina, which is manufactured for our specific customers.

iron free refractory bed materials

we use virgin material to manufacture iron free bed material. it has above 50% alumina content. the specific feature of this product is that it provides dense refraction.

fbc boiler

fluid bed combustion (fbc) has emerged as a viable alternative for conventional firing system. it has significant advantages and offers multiple benefits due to which fbc model has an added advantage over the other.

the fbc will take place at about 8400o c to 9500o c . since the temperature is much below the melting of ash and associated problem are avoided.

the gas velocity is maintained between minimum fluidization velocity and particle entrainment velocity. this ensures static operation of the bed and avoids particle entailment in the gas stream.

the important feature of the atmospheric fluidized bed combustion is the constraint imposed by the relatively narrow temperature range within which the bed must be operated. with coal, there is risk of clinker formation in the bed if the temperature exceeds 9500o c and loss of combustion efficiency if the temperature falls below 8000o c. for efficient sulphur retention, the temperature should be in the range of 8000o to 8500o c

the distribution plate is protected from high temperature of the furnace b

refractory lining

a static layer of the bed material

water cooled tubes.