Listing ID #3871628

Company Information

Ask for more detail from the seller

Contact Supplier

|

||||||||||||||||||||||||||||||||||||||||||||||

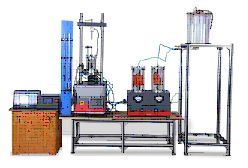

| PC-based Retrofit Systems GEAR MAS™ for : - | ||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||

| Pitch & Runout Attachment for Gear Tester of any make : Gear MAS™II is a State of Art PC based Measurement & Analysis System for Inspection of Gear Pitch & PCD Runout. |

||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||