Listing ID #2634617

Company Information

Ask for more detail from the seller

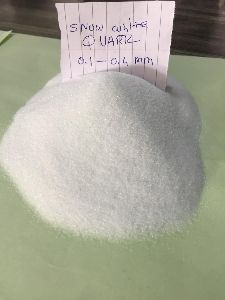

Contact SupplierWe work in close coordination with the team members and packaging professionals; they ensure that the products are packed sternly using the finest quality packaging materials. In order to ensure complete satisfaction of the customers, we deliver the orders on the scheduled time. Preparation Procedure Quartz Grains & Powder (Quartz Grains, 0-5 MM*) is for high performance at high temperature during melting in coreless induction furnace, with an added advantage of reducing slag deposit. While preheating it to a temperature of 100-150o C for removal of moisture particles, it is imperative to ascertain that there are no impurities during this process. At the next step after procuring the material by our valued clients this requires to be mixed with Boric Acid once the mass is cooled below 40o C. The percentage of which varies from 0.8-1.4%, depending upon the operating temperature. Quartz is used in small capacity induction furnace, as its low resistance to high temperature thus minimizing the cost of production, while maintaining the productivity and quality of product. Moreover, Gajanan Group ensures that the composition of the Quartz Grains & Powder (Quartz Grains, 0-5 MM*) is optimized on the basis of the furnace capacity to achieve better bulk density. At Gajanan, the processing unit is completely automated, no man-power, so that question of an error is negated. The unit is further furnished with heavy-duty magnets of 12,000 gauss, so that the final product contains no free iron in it which gets generated during the process, as iron content causes immense damage to the furnace.

| Contents | Percentage % | |

|---|---|---|

| Silica | SiO2 | 0.9868 |

| Alumina | AI2O3 | 0.0008 |

| Ferric Oxide | Fe2O3 | 0.0003 |

| Titanium Oxide | TiO2 | 0.0008 |

| Manganese Oxide | MnO | 0.0011 |

| Sodium Oxide | Na2O | 0.0005 |

| Loss on Ignition | - | 0.0083 |

| Sintering Temperature | - | 1200 o C |

| App Temperature | - | 1600 o C |