Company Information

Ask for more detail from the seller

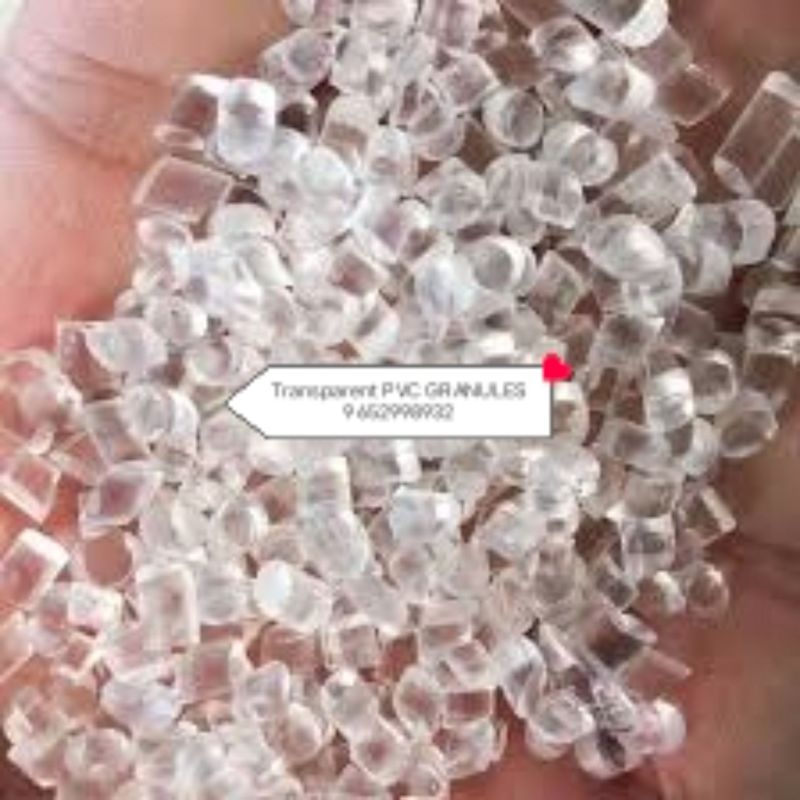

Contact SupplierPolyvinyl chloride (PVC) granules are commonly used in the manufacturing of cables. PVC is a versatile and durable thermoplastic material that has several properties that make it suitable for cable insulation and sheathing. Here's some information about PVC granules for cable applications:

1. **Insulation:** PVC granules are often used to make the insulation of electrical cables. PVC provides excellent electrical insulation properties, protecting the conductors within the cable from external environmental factors.

2. **Sheathing:** PVC granules are also used for the outer sheathing of cables. This protective layer adds an extra level of insulation and provides mechanical protection to the cable, making it resistant to physical damage, moisture, and chemicals.

3. **Flame Retardancy:** Many PVC formulations used for cables are flame-retardant, which means they have additives to reduce the risk of the cable catching fire or spreading flames in case of a fire event.

4. **Chemical Resistance:** PVC is known for its resistance to a wide range of chemicals, which can be important in cable applications, especially when the cable is exposed to various environmental conditions.

5. **Temperature Resistance:** PVC cables can be designed to operate within a wide range of temperatures, making them suitable for both indoor and outdoor applications.

6. **UV Resistance:** Some PVC formulations are designed to be UV-resistant, which means they can withstand prolonged exposure to sunlight without degrading or becoming brittle.

7. **Flexibility:** PVC cables can be flexible or rigid, depending on their intended use. Flexible PVC cables are often used in applications where the cable needs to bend or move, such as in extension cords.

8. **RoHS Compliance:** Many PVC cable formulations comply with regulations such as the Restriction of Hazardous Substances (RoHS), which restricts the use of certain hazardous materials in electronic and electrical equipment.

It's important to note that PVC has been a subject of environmental and health concerns due to the release of toxic chlorine gas when it burns and the presence of plasticizers like phthalates in some formulations. As a result, there has been a push in some regions to develop alternative materials for cables, such as low-smoke, zero-halogen (LSZH) compounds. These materials produce less toxic smoke when burned and are more environmentally friendly. However, PVC remains widely used in cable manufacturing due to its cost-effectiveness and performance characteristics.

When selecting PVC granules for cable manufacturing, it's crucial to consider the specific requirements of the cable, such as its intended use, environmental conditions, and regulatory compliance. Manufacturers often customize the PVC formulation to meet these specific needs.