Listing ID #3239268

Company Information

Ask for more detail from the seller

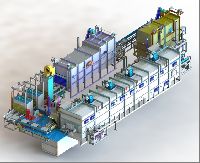

Contact SupplierPusher Furnace Electric or Gas or Oil Knackwell manufactures Pusher Furnaces in either electric or gas or Oil fired heating systems. The design of the heating systems provide for shielding of the loads from the detrimental effects of direct radiant heat or flame impingement while promoting efficient uniform heating of the loads. Electric Heating Systems Electric Pusher Furnaces employ various styles of resistance type electric heaters to maintain the integrity of the furnace atmosphere and thermal efficiencies. Heaters can be supplied as either standard open resistance wire/strip type. Thyristor power controllers with control panel door mounted diagnostics displays are standard for Knackwell Pusher Furnaces, with optional PLC and PC systems integration available. Heating systems are factory pre wired to meet NFPA standards where applicable, and all equipment is factory tested prior to shipment. Gas Firing Systems Gas fired furnaces employ either direct gas firing or indirect style gas firing burners to maintain the integrity of the furnace atmosphere.

Following burner types can be supplied by Knackwell :

Solid state flame supervision systems with panel door mounted diagnostics displays are standard for Knackwell Pusher Furnaces, with optional PLC and PC systems integration available. Combustions systems are factory prepiped to meet NFPA standards where applicable, and all equipment is factory tested prior to shipment. For applications requiring advanced Pusher Furnaces for continuous production, KNACKWELL has a large family of standard and customizable solutions. These furnaces are designed for the tight control of temperature and atmosphere necessary for processes with long residence times that require exact control. Our systems can safely operate in air, hydrogen, inert and most reducing gas environments. Our focus is on systems that offer the greatest operating life, lowest operating cost, and highest efficiency in your production line. All our pusher furnace designs incorporate high grade alumina ceramic fiber or brick insulation, heavy duty heating elements / Burners, and advanced wall construction designs for a long lifetime of low maintenance operation.Typical configurations of our pusher furnaces include preheat sections, soaking section, and cooling sections

Knackwell pusher furnaces see use in industries such as:

Knackwell pusher furnace models incorporate a modular design approach that is highly customizable to the needs of clients. Our customized continuous production furnaces have served many industries requiring complex soak profiles. With Knackwell's long experience in production furnace construction, you will find a partner with both standard and customized furnaces who can meet your needs reliably.

Our Engineered Thermal Solutions will allow for flexibility in your manufacturing productivity with following advantages: