Listing ID #1709993

Company Information

Ask for more detail from the seller

Contact SupplierDescription

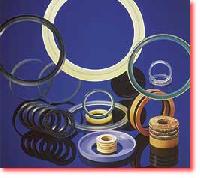

Virgin PTFE and filled PTFE seals are used where minimum friction, wide temperature range and maximum media resistance is required.

Application & Usage1. Used mainly for O-Rings, backup rings and machined parts used in special applications requiring chemical inertness and limited strength. Ideal for use in cryogenic applications. Used in light duty very slow reciprocating and static applications subject to high wear.

2. Used in dynamic sealing applications where the bronze filler gives improved wear resistance, hardness and compressive strength. The electrical properties and chemical resistance are reduced. Molybdenum disulphide improves the self lubrication.

3.Significant increased thermal conductivity, reduced level of creep, self lubricating, therefore suitable for high speed application, without the need for exterior lubrication and applications which need to remove thermal energy and/or static electricity. High performance material with excellent wear resistance.

4. Used where there is a need for improved wear and increased coefficient of friction. Ideal for high dynamic applications. E.g.: High rotation pumps. Excellent to cryogenics Helium, Hydrogen and Oxygen. 5. Used at operating temperatures above 175°C.

Materials usedVirgin PTFE, Bronze Filled PTFE, Graphite Filled PTFE, Glass filled PTFE, Peek, Polyfill etc.