Listing ID #3448169

Company Information

Ask for more detail from the seller

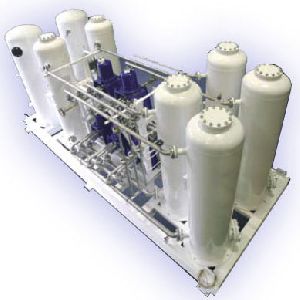

Contact SupplierThe PSA hydrogen-unit consists of four or more adsorption towers. Each of these towers passes subsequently through the stages of pressure build up, adsorption and regeneration. By this a continuous supply of product gas can be achieved. The pressure build up is carried out in one or more steps.The tower in adsorption is switched over to regeneration. During this step,hydrogen enriched gas flows to another tower for the next adsorption step.

The remaining part of the pressure build up is done with product gas. In the subsequent production step, feed gas is passed through the adsorption tower and hydrogen with very high purity leaves the tower.The regeneration is also done in several steps.

After pressure equalization with the previously regenerated adsorption tower, the present adsorption tower is depressurized. This is followedby a purge step with a counter-current flow of hydrogen.In casethere is a high concentration of heavy hydrocarbons in the feed gas, a pre-filter system is integrated into the PSA-process.