Listing ID #1897484

Company Information

Ask for more detail from the seller

Contact SupplierThe Orchestra of Industry: A Deep Dive into Process Control Instruments

In the grand symphony of industrial production, process control instruments play a vital role as the conductor, ensuring all elements work in harmony to achieve a flawless performance. These unsung heroes silently measure, monitor, and adjust various parameters within a process, guaranteeing consistent quality, efficiency, and safety.

Here, we delve into the world of process control instruments, exploring their intricate details and creative applications:

The Essential Players:

· Sensors and Transducers: These are the eyes and ears of the process, gathering real-time data on crucial parameters like temperature, pressure, flow rate, and liquid level. Imagine a pressure sensor acting like a meticulous percussionist, keeping beat with the pressure fluctuations within a pipe.

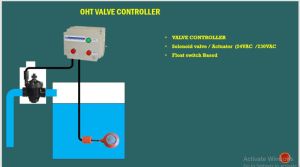

· Controllers: The brain of the operation, controllers analyze the data received from sensors and compare it to pre-defined setpoints. Based on these comparisons, they send instructions to adjust control elements, ensuring the process stays within the desired parameters. Think of the controller as the conductor, interpreting the sensor data and directing the control elements like a skilled maestro.

· Control Elements: These are the workhorses of the process, physically manipulating various aspects based on the controller's instructions. A control valve, for example, acts like a skilled trumpet player, adjusting the flow rate of a liquid by opening or closing based on the controller's commands.

· Final Control Elements: These are the final actuators that directly influence the process variables. A heater, for instance, functions like a passionate violinist, increasing or decreasing heat based on the controller's instructions to maintain the desired temperature.

The Symphony in Action:

Imagine a petroleum refinery – a complex dance of various processes. Temperature sensors, like watchful oboists, monitor the temperature within reactors. Pressure sensors, vigilant like timpanists, keep track of pressure levels in pipelines. The collected data streams to the controller, the conductor analyzing the information. If the temperature deviates from the setpoint, the controller sends signals. A valve, acting as a responsive flutist, adjusts the flow rate of a coolant, bringing the temperature back into harmony. This continuous monitoring and adjustment by process control instruments ensures the smooth operation of the refinery, producing high-quality fuel with optimal efficiency.

Beyond the Basics: Creative Applications:

Process control instruments are not limited to large-scale industrial settings. Here are some creative ways they are used:

· Food Production: Maintaining precise fermentation temperatures in breweries or ensuring consistent baking temperatures in ovens.

· Environmental Monitoring: Tracking air quality in urban areas or monitoring water levels in reservoirs.

· Pharmaceutical Manufacturing: Ensuring sterile conditions and precise dosages during drug production.

· Smart Homes: Regulating temperature and humidity levels for optimal comfort and energy efficiency.

The Future Symphony: Advancements and Innovations:

The world of process control instruments is constantly evolving. Here's a glimpse into the future:

· The Rise of Automation: Artificial intelligence and machine learning will play a greater role in process optimization and anomaly detection.

· Wireless Connectivity: Instruments will communicate wirelessly, enabling remote monitoring and control.

· Advanced Sensor Technologies: Sensors with greater sensitivity and wider ranges will provide even more precise data.

· Focus on Sustainability: Instruments will be designed to improve energy efficiency and reduce environmental impact.

The Enduring Value:

Process control instruments may not be the most glamorous aspect of industry, but their role is undeniable. They ensure consistent product quality, efficient operations, and safety across various sectors. As technology advances, these instruments will become even more sophisticated, composing a future symphony of industrial excellence.

The Melody of Maintenance: Keeping the Instruments in Tune

Just like any musical instrument, process control instruments require proper care and maintenance to perform at their best. Here's a look at the key aspects of keeping your industrial orchestra in perfect harmony:

· Calibration: Regularly calibrate sensors and other instruments using certified standards to ensure accuracy. Imagine a piano tuner meticulously adjusting the strings to ensure each note resonates perfectly.

· Preventative Maintenance: Schedule routine inspections and cleaning to prevent problems before they arise. Think of this as wiping down your instruments after a performance to maintain their longevity.

· Diagnostics and Troubleshooting: Utilize built-in diagnostic features or specialized tools to identify and address instrument malfunctions promptly. This is akin to a musician recognizing a faulty string and replacing it before the next piece.

· Training: Ensure personnel responsible for operating and maintaining the instruments are adequately trained.

· Spare Parts Inventory: Maintain a readily available stock of critical spare parts to minimize downtime in case of failures. Imagine having a spare set of strings readily available in case one breaks during a concert.

The Composer's Touch: Selecting the Right Instruments

Choosing the appropriate process control instruments for your specific application is crucial. Here's a composer-like approach to selecting the right tools for the job:

· Process Needs: Identify the critical parameters that need to be monitored and controlled within your process. What is the conductor trying to achieve?

· Accuracy Requirements: Determine the level of precision needed for the measured variables. How critical are the nuances of each note?

· Environmental Conditions: Consider factors like temperature, pressure, and potential presence of corrosive materials. Can the instruments withstand the environment like a well-crafted instrument can endure a long concert?

· Cost and Budgetary Constraints: Balance the desired features and functionality with your budgetary limitations. How much can the orchestra afford to invest in its instruments?

· Scalability and Future Needs: Think about the potential for future expansion or changes in your process. Will the instruments be adaptable to future variations in the musical composition?

By carefully considering these factors, you can select the ideal process control instruments that will become the building blocks of a successful and efficient industrial operation.

The Encore: The Impact of Process Control Instruments

The impact of process control instruments extends far beyond the factory floor. Here are some of the lasting benefits they bring:

· Improved Product Quality: Consistent monitoring and control ensure products meet specific quality standards. This translates to a flawless performance every time, like a perfectly executed musical piece.

· Enhanced Safety: By preventing process upsets and equipment failures, process control instruments contribute to a safer working environment for personnel.

· Reduced Costs: Efficient operation and minimized waste lead to lower production costs. This allows the orchestra to focus on delivering a high-quality performance without unnecessary expenses.

· Environmental Protection: Precise control of processes helps reduce emissions and waste, contributing to a more sustainable future. It's like composing a beautiful symphony that is also harmonious with the environment.

Process control instruments are the unsung heroes of industry, silently orchestrating a symphony of efficiency, quality, and safety. By understanding their intricacies, creative applications, and the importance of maintenance, we can ensure these instruments continue to play a vital role in our industrial endeavors.