-

Supply Type

Manufacturer, Exporter, Supplier

-

Preferred Buyer Location

All over the world

APPLICATION :

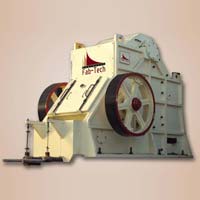

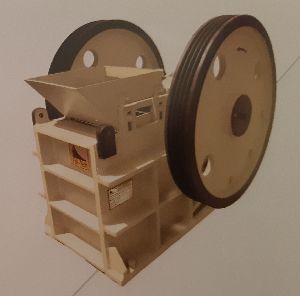

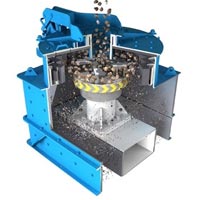

MARSMAN* Primary Jaw Crushers are ideally suited for crushing of hard granite stone, black trap rock, river gravel, lime stone coal, iron etc. at primary stage ....

View More Details