Listing ID #4380694

Company Information

Ask for more detail from the seller

Contact SupplierSuper Blast - SB

Works on INDUCTION - SUCTION principle of abrasive delivery. The super blaster ensures continuous working and no interruption in blasting cycle. Recommended for light and medium sized components where surface is to be cleaned or deburred or to impart with fine matte finish. Useful for heat treatment shops, tool, die and mould makers and shot peening of light metal components etc. SB machines are incorporated with reclaimer which ensures uniform cleaning and finishing each time and in every next operation. This is achieved by an automatic system of abrasive cleaning and separation built into the reclaimer. Dust and debris are separated and only clean and sized abrasives are carried to clast gun-ensuring a homogeneous finishing. Most cabinets of other make do not have the reclaimer as standard practice.

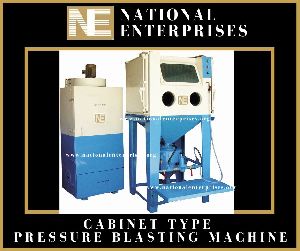

Pressure Blaster - PBWorks on DIRECT PRESSURE principle of blasting, the pressure blaster produces high abrasive velocity resulting to cleaning of job at faster rate. A pressure vessel directly bolted below hopper of cabinet has automatic abrasive refilling arrangement. A tubular fabric bag type dust collector with generous filter area is attached with cabinet as standard feature for high efficiency of dust collection. A manual shaker is also provided for bag shaking PB is recommended for fast cleaning, for removal of heavy rust and corrosion using coarse abrasive, it is most suitable for etching the surface needed for rubber-lining. FRP lining and metal spaying. Castings and forgings are cleaned speedily. Blast pressure can be controlled from 30 to 90 psig. Almost all types of coarse and medium size abrasives can be used depending upon application.

Wet Blaster - WBWorks on INDUCTION - SUCTION principle of blasting. The most important point in wet blasting is its ability to use very fine abrasive - as fine as 5 microns. Fine abrasive are suspended in liquid, usually water and then pumped to a nozzle as a slurry. At nozzle, the slurry is introduced into air - stream and propelled against job. The glandless slurry pump is used to feed the slurry at positive pressure into blast gun. The wetter parts of pump are of thermoset plastic material for corrosion resistance. WB machine is useful in tool room to remove feather burrs multi-tooth cutting tools, such as, milling cutter holes, broaches and taps eliminating hours of hand honing time. It deburrs intersecting holes in precision parts which are inaccessible by any other method. The finest machined surface can be super-finished without damage to sharp edges and exact tolerances.

| Model | Pressure Blaster(PB) | Super Blaster(SB) | Wet Blaster(WB) | |||||

|---|---|---|---|---|---|---|---|---|

| PB - 9182 | PB - 12090 | PB - 150120 | SB - 6060 | SB - 9182 | SB - 12090 | WB - 9182 | WB - 12090 | |

| Working Chamber (mm) Height Weight Depth |

775 910 820 |

900 1200 900 |

900 1500 1200 |

600 600 600 |

775 910 820 |

900 1200 900 |

775 900 820 |

900 1200 900 |

| Door Opening (mm) Weight Height |

730 675 |

800 800 |

1100 800 |

500 500 |

730 675 |

800 800 |

730 675 |

800 800 |

| Overall Dimension (mm) Height Weight Depth |

2130 1100 2500 |

2030 1365 2430 |

2080 1665 2730 |

1660 800 1500 |

2120 1070 1400 |

2570 1365 1700 |

1940 1070 1500 |

2235 1365 1700 |

| Dust or Mist Collector or Reclaimer Fan Motor HP Fan Capacity (M3/min) Fan Capacity (CFM) Filter Cloth Area (M2) Slurry Pump Motor (HP) Airjet Orifice (mm) Blast Nozzle (mm) |

1.0 14.16 500 7.5 --- --- *5,6 |

1.0 14.16 500 7.5 --- --- *5,6 |

1.5 22.66 500 7.5 --- --- *5,6 |

0.5 5.66 200 1.0 --- *2,3 *6,8 |

1.0 11.32 400 2.0 --- *3,4,5.5 *8,10,12 |

1.5 16.98 600 4.0 --- 3,*4,5.5 8,*10,12 |

0.5 5.66 200 --- 1.0 *3,4,5.5 *8,10,12 |

1.0 11.32 400 --- 1.0 *3,4,5.5 *8,10,12 |

| Abrasive Storage Capacity Litres (CFT) Pit Size (mm) Weight Length Depth Weight in Kg (approx.) |

28 (1.0) --- *5,6 |

42 (1.5) 600 2180 510 650 |

42 (1.5) 900 2530 600 760 |

28 (1.0) --- 250 |

28 (1.0) --- 380 |

42 (1.5) --- 490 |

42 (1.5) --- 400 |

42 (1.5) --- 525 |

| Abrasive Feed | Direct Pressure | Induction Suction | Glanless Pump | |||||