Listing ID #4304577

Company Information

Ask for more detail from the seller

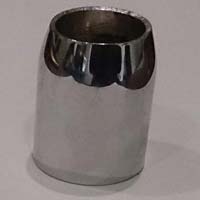

Contact SupplierPre Stressed Metallic Sleeve » General

The pre-stressed metallic sleeves supplied are used for pipeline defects repair by the shielded metal arc welding process (SMAW). The pipelines repaired are manufactured by the Electric Resistance Welding (ERW) technique. The specification of material of construction is API 5L Gr B, X42, X46, X52, X56, X 60, X 65, X70 - PSL 1 - PSL2 (minimum yield 245000 / 52000 / 60000 / 65000 / 70000), ASTM A36 (structural; minimum yield 36,000 psi), ASTM A572 GR42, GR50, GR55, GR60, GR65 (structural; minimum yield 29,000 psi), ASTM A516 GR55, GR60, GR65, GR70 (pressure vessel; minimum yield 38,000 psi), ASTM A537 Class I, Class 2, Class 3 (pressure vessel; minimum yield 50,000 psi), EN 10025 - S235, S275, S355, S450 The pipelines nominal size is 2" NB to 60" OD and Thickness 4 mm to 100 mm.

» Design & ConstructionThe pre-stressed sleeves are of full encirclement split type and are manufactured by a production process, that minimizes occurance mill defects. Axial edges of the sleeves are bevelled to form 60° weld angle on assembly for the horizontal butt joint. A recess on the inner side of each pair of half sleeves is machined (cut out) to accommodate a 3 mm thick by 18 mm wide backing strip along the horizontal joint. The backing strips are manufactured from the same material as the sleeves and supplied. Circumferential edges of the sleeves is pre-fabricated to form 90° lap joint with the pipe.

The internal diameter of the sleeves is designed and constructed so as to fit on the pipe withour leaving a gap between the inner surface of the sleeve and outer surface of the pipe all around.

On assembly prior to welding, the maximum root gap shall be 3.0 mm on both horizontal joints. A 1.5 mm root face shall be allowed on both edges.

Both the horizontal and circumferential edges shall have a smooth finish.

The sleeve surfaces shall be protected from corrosion by a suitable method such as coating with corrosion resistant paint or other acceptable methods.

Lightweight for easy handling and installation.

Eliminates costly downtime.

Minimizes repair costs.

The Sleeves shall be manufactured to the standard lengths of 1.0 m and 3.0 m for any diameter of pipe.

The backing strips shall be manufactured in standard lengths of 3m.

Material used are structural quality carbon steel or pressure vessel quality carbon steel plates, which are to ASTM specifications, and in the following grades:

API 5L Gr B, X42, X46, X52, X56, X 60, X 65, X70 - PSL 1 - PSL2 (minimum yield 245000 / 52000 / 60000 / 65000 / 70000)

ASTM A36 (structural; minimum yield 36,000 psi)

ASTM A572 GR42, GR50, GR55, GR60, GR65 (structural; minimum yield 29,000 psi)

ASTM A516 GR55, GR60, GR65, GR70 (pressure vessel; minimum yield 38,000 psi)

ASTM A537 Class I, Class 2, Class 3 (pressure vessel; minimum yield 50,000 psi)

EN 10025 - S235, S275, S355, S450

The chemical composition does not exceed the percentages specified for the ASTM material ordered. Repair sleeves are fabricated from plate with low carbon equivalency for good weld ability.

The maximum allowable carbon equivalency (CE) quality carbon steel plates will be based on the heat analysis.

The maximum allowable carbon equivalency (CE) pressure vessel quality carbon steel plates will be based on the heat analysis, in most cases.

Note : The sleeve can be manufactured in any grade as per the application & client requirements.

» Mill Test CertificateMill test certificate will be provided for the whole batch supplied, accordingly.

» PackingThe Sleeves shall be packed in wooden boxes suitable for outdoor storage. These boxes will be constructed so as to allow handling with either overhead crane or fork lift or mobile Crane.

The 2 pieces comprising a pair of sleeves will be clearly marked for ease of identifaction of matching parts.

Each box will be clearly marked to indicate size, length and number of complete pair of sleeves packed therein. These markings will be made by indelible ink that can withstand adverse outdoor weather effects.

The sleeves will be packed seperately according to their length.

An appropriate packing material shall be used to separate individual pieces so as to avoid damaging the corrosion resistant paint coating.

The backing strips will be packed in fully enclosed wooden boxes. This boxes shall be constructed so as to allow opening and closing of the top side to ease the removal of strips.

We can manufacture Pre-stressed Metallic Sleeve for any size depending on the client's requirement.