Listing ID #4380684

Company Information

Ask for more detail from the seller

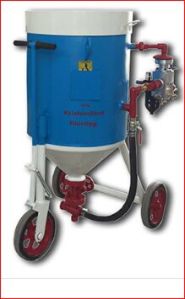

Contact SupplierAll standards models of Portable Abrasive Blaster are available with and without Remote Control Version.

In five standard models having cleaning rate from 3 to 20 sq-meter/hr.Tungsten carbide venturi nozzles in 5mm, 6mm, 8mm, 10mm, 12mm bore. Air requirement varies as per model from 45 cfm to 250 cfm at 80 psi.

1) Automatic Filling Value :

The machine is provided with automatic musroom valve (Filling Valve) for quick refilling of abrasive.

2) Tungsten Carbide Venturi Nozzle :

The long & short series convergent-divergent tungsten carbide lined blasting nozzle ensures high velocity, evently distributed blast pattern & higher blasting output and provides lower wear, longer life and greater resistance against breakage.

3) Blast Hose :

The blast hose is highly abration resistance with improved mixing valve outlet for longer life, high flexibility with lower bend radius & light weight and electrically antistatic for safe operation.

4) Abrasive Control Valve :

The machine is fitted with pinch valve with hand wheel to control the abrasive flow through blast nozzle.

5) Abrasive Sieving :

A wirw screen is fitted with pneumatic vibrator to sieve abrasive to avoid blast line choking.

6) Abrasive Tank Construction :

Abrasive tank is fabricated from tested quality steel plate in accordance with IS-2825 and hydraulically tested at 250 psi.

7) Automatic Exhaust Valve :

It vents outlet air and thereby machine is depressurised instantly. Valve opens automatically with stop of air supply to machine and vice-versa.

8) Air Filter & Pressure Gauge :

An online air filter and pressure gauge is provided.

9) Ball Valve :

The machine is fitted with ball valve having stainless steel ball (An anti-corrosive material) to ensure full air flow without pressure loss.

| P7 - 150 | P7 - 301R | P7 - 501R | P7 - 601R | P7 - 1001R | P7 - 901R (with dual outlet) |

|

|---|---|---|---|---|---|---|

| Abraisive Capacity Metalic (Kg.) Sand (Kg.) Volume (Liters) |

150 65 42 |

300 130mm 85 |

500 230 142 |

600 275 172 |

1000 460 284 |

900 400 255 |

| Overall Dimensions approx Height mm Diameter mm Weight Kg. |

1110 360 95 |

1290 460 140 |

1370 615 180 |

1500 615 200 |

1610 760 245 |

1610 615 220 |

| Blast Nozzle Tungsten Carbide lined Oriffice mm [*Standard size supplied unless ordered otherwise] |

*5 6 |

*6 5 |

*8 6, 10 |

*8 6, 10 |

*10 8, 12 |

*10 8, 12 |

| Blast Hose ID (mm) Blast Hose Length (meter) Recommended Air Hose ID (mm) |

19 5 19 |

19 5 19 |

25 7.5 25 |

25 10 25 |

32 10 32 |

32 10 32 |

| Approx Cleaning Eate (Sq. Mtr./Hour) For guidance only |

3 to 4 | 5 to 9 | 11 to 15 | 11 to 15 | 15 to 19 | 15 to 19 |

| Compressed Air Requirement at 5.63 Kg./sq. Cm (80psi) Cubic meter/minute (CFM) |

1.27(45) | 2.41(85) | 3.85(135) | 3.85(135) | 7.08(250) | 7.08(250) |

| Recommended Abraisive size range BS Mesh |

30 to 80 | 25 to 80 | 16 to 80 | 16 to 80 | 12 to 80 | 12 to 80 |