Company Information

Ask for more detail from the seller

Contact SupplierIntroduction:

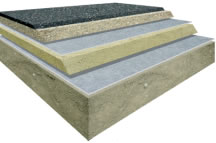

Non-Woven Geotextile are needle punched fabrics made from polypropylene. The dry laid needle punch technology is based on a two step process. Firstly, polypropylene resin is extruded into fibres. Secondly, the fibres are carded and needlepunched. Finally, some types are added thermal treatment. Weights range from 100 g/m2 up to 1200 g/m2.

Functions of Non-Woven Geotextile:

Primary Functions:

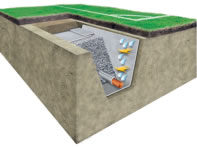

Separation

The durability and mechanical properties of Non-Woven Geotextiles make them ideal as separating layers in construction works.

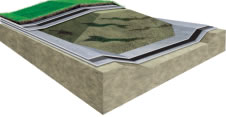

Filtration

The characteristic opening size of Non-Woven Geotextiles is designed to retain particles while allowing free movement of water, making it possible to separate two layers during intense hydraulic activity.

Protection

When placing a Non-Woven Geotextile on both sides of a waterproof membrane, the thickness and strength of the geotextile protect the membrane from puncture.

Secondary Function:

Drainage

Excess water is drained off the construction - not by passing through the Non-Woven Geotextile as when used for filtration - but by flowing in the plane of the geotextile leading it away from the construction.