Listing ID #3690937

Company Information

Ask for more detail from the seller

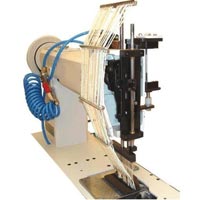

Contact SupplierLiquor dosing by highly efficient over head mounted JOGSON Pneumatic Actuated Distribution system

Automatic dyeing cycles, high productivity, 1 dyeing cycle in about 60 seconds

Suitable for any type of yarn natural or synthetic, wound on dye spring, plastic tube, steel tube, etc.

Suitable for dyestuff like Acid, Reacted , Direct, Disperse and Pre-metallized

Multiple design possibilities

Power control panel with PLC & touch interface

Floor level installation

Individual colour tanks for stocking dyestuff

Step Working

Package Preparation : The yarn must be wound on Dye Spring, Plastic Tube, Steel Tube, etc.

Recipe preparation : The chemicals & dye-stuff are mixed & put into colour tank

Dyeing process : It starts with transferring of mixed liquor from each colour tank to overhead dosing cylinders & distributed uniformly to the package. The uniformity of the printed package is guaranteed both by JOGSON Pneumatic Actuated Distribution system mated with high suction of the vacuum pump

Dyestuff Fixation : After dyeing, the package are placed in JOGSON Yarn Conditioning Machine for dyestuff fixation. The process of heat setting & conditioning varies on the type of yarn

Washing : To wash out the excess dyestuff the package is then placed in JOGSON yarn dyeing machine

Drying : Depending on the Yarn, JOGSON Hydro Extractor or JOGSON Hot Air Drier can be used to dry the wet package