Listing ID #4015214

Company Information

Ask for more detail from the seller

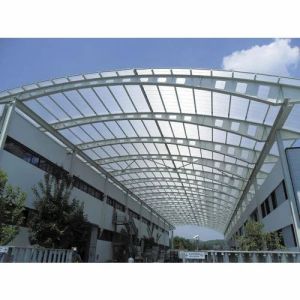

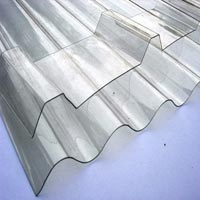

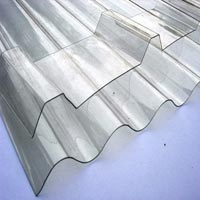

Contact SupplierBeing PIONEER in manufacturer of Rooftop “KatWalk” and Rooftop “KatNet” systems since 1980, naturally the problem of accidents through such translucent sheets was entrusted to us by many leaders in Indian Industry. We came out with the solution which is approved by them. The “KatNet” system is modified and fixing is devised in such a way that the sheets can be differentiated at a distance. These nets negligibly reduce light passage. Thus stepping on these sheets can be avoided. Even if unconsciously, unintentionally some one steps on it the sheet may get damaged, but, the worker shall remain SAFE. This solution, to avoid accidents, is economical than any other equipment.

“KatNet” salient features:

With recent introduction of this product, many industries are coming forward to choose this system and do away with the basic problem.

These “KatNet” nets are required to be tailor-made since the sheet profiles in metal sheets are not standardised.