Listing ID #6149366

Company Information

Ask for more detail from the seller

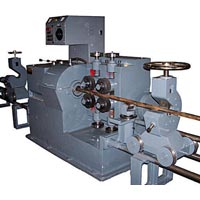

Contact SupplierKNTM Brand Pneumatic Shears fabricated from IS-2062 graded. Rolled steel plates. Table and cutting beam are deeply reinforced and fines machine after stress reliving. The interlocked design put the direct support to frame. Thus frames are strain free and eliminate welds at load support. Thus the accuracy of the machine is never disturbed.

FRAME CONSTRUCTION

Pneumatic Under Crank Shearing machine Frame fabricated from IS-2062 graded. Rolled steel plates. Table and cutting beam are deeply reinforced and fines machine after stress reliving. The interlocked design put the direct support to frame. Thus frames are strain free and eliminate welds at load support. Thus the accuracy of the machine is never disturbed.

BED

Super strong bed of closed box type construction, Street relieved in a furnace, forms a rigid backbone for the shear and a solid backing for the lower knife. Dovetail slots in front of the bed are provided for front gauge. Slots on top of bed area also provided for machined pas across the bed for convenient setting of front gauge brackets any desired spacing. Depressions in the top at the bed provide ample clearance for fingers in handling sheets narrower than the bed.

UPPER BEAM

Ram is also of solid steel plates, carrying the upper knife. Its minimum weight ensure lesser load on the bearings, The upper beam moves in flat heat treated steel guide plates to avoid plates to avoid deflection, for smooth running and maintain the accurate straightness of the upper knife.

HOLD-DOWN MECHANISM

Solid clamping by powerful spring loads hold down is one of the reasons for accuracy in our shears. Heavy uniform pressure is applied along the full length of the work piece, preventing slippage regardless of versions in thickness. Hold down pressure in easily adjustable for clamping soft material. Different thickness of material can be cut without future adjustment with consistently accurate and burr free results.

ROLLING KEY CLUTCH

Made of alloy steel for positive engagement and continuous operation having three key ways. Single rolling key system is incorporated in the machine ensuring easy and efficient working of the machine.

SHEAR KNIVES

Knives are manufactured strictly as per standard material of D2 HCHCr. Every step from designing metallurgical specifications, heat treatment, grinding and inspection is carefully controlled. The blades are standards are standardized and are easily replaced.

ACCURATE GAUGING

The Rigid and accurate construction of the back gauge provided with the machine allows consistency in the width of sheets being cut.

LUBRICATION

Single shot lubricator provides oil to all the lubrication points, when necessary. Thus, all bearing parts and guide surface etc.

DRIVE

Drive through V-belts on flywheel and reduction gears are made of steel, hob cut for the smooth running and longer life.

| MODEL NO. | KNTM – 1/POC | KNTM – 1.250/POC | KNTM – 2/POC | KNTM – 2.5/POC | KNTM – 3/POC | KNTM – 4/POC |

|---|---|---|---|---|---|---|

| SHEARING LENGTH | 1000 MM | 1250 MM | 2000 MM | 2500 MM | 3000 MM | 4000 MM |

| SHEARING CUTTING THICKNESS AS PER MS TENSILE STRENGETH | 06 – 16 MM | 06 – 16 MM | 06 – 16 MM | 06 – 16 MM | 06 – 16 MM | 06 – 16 MM |

| DEPTH OF THROAT | 175 | 175 | 175 | 175 | 175 | 175 |

| BACK GAUGE RUNNING LENGTH | 0.5 – 600 MM | 0.5 – 600 MM | 0.5 – 600 MM | 0.5 – 600 MM | 0.5 – 600 MM | 0.5 – 600 MM |

| BLADES TESTED GRADE | D2 | D2 | D2 | D2 | D2 | D2 |

| BLADES SIZE | 1050 X 100 X 25 MM | 1270 X 100 X 25 MM | 1025 X 100 X 25 MM | 1270 X 100 X 25 MM | 1550 X 100 X 25 MM | 1350 X 100 X 25 MM |

| NOS. OF BLADES FITTED | 2 | 2 | 4 | 4 | 4 | 6 |

| STROKES PER MINUTES | 55 – 58 | 55 – 58 | 52 – 55 | 52 – 55 | 48 – 50 | 45 – 48 |

| ELECTRICAL MOTOR OF ABB CO. MAKE. (HP X 1440 RPM) | 7.5 – 10 - 15 | 7.5 – 10 – 15 | 10 – 15 – 20 | 10 – 15 – 20 | 15 – 20 – 25 | 15 – 20 - 25 |

| FRONT SHEET SUPPORT ARMS LENGTH | 600 | 600 | 600 | 600 | 600 | 600 |

| PNEUMCATIC CLUTCH KPM | 400 | 400 | 400 | 400 | 400 – 600 | 400 - 600 |

Keshav New Tech Machines (India) Pvt Ltd, founded in 1989, is a manufacturer of a wide range of technical equipment utilised in many sectors. In the competitive area of Hydraulic Press Brake, Hydraulic Shearing Machines, Cut To Length Machine, and so on, we are a company to be reckoned with in Bahadurgarh, Haryana.

Our zealous attitude, stringent quality control processes, and scientific R&D activities have propelled us to a position that attests to the excellence of our product line.

We have held a leading position in the international Machine Industry by using the expertise and capabilities of our professional staff. Furthermore, our purposeful and planned progression has aided us in coping with diverse commercial procedures.

Our Infrastructure:

We have a robust infrastructure that aids in the modernization of our manufacturing operations. All of our units work tirelessly to provide our customers with an unrivalled selection of equipment that meets worldwide standards. Aside from that, our manufacturing plant is fully functioning and equipped with cutting-edge machinery.

Why Us?

Some of the causes why we are the customers' first choice are as follows:

● Improved reporting system to keep customers informed on a regular basis so that they can plan their purchases.

● A group of competent engineers who are up to date on the latest innovations

● Constant process development in order to attain optimum client satisfaction