Listing ID #4274953

Company Information

Ask for more detail from the seller

Contact Supplier» Product Details: -

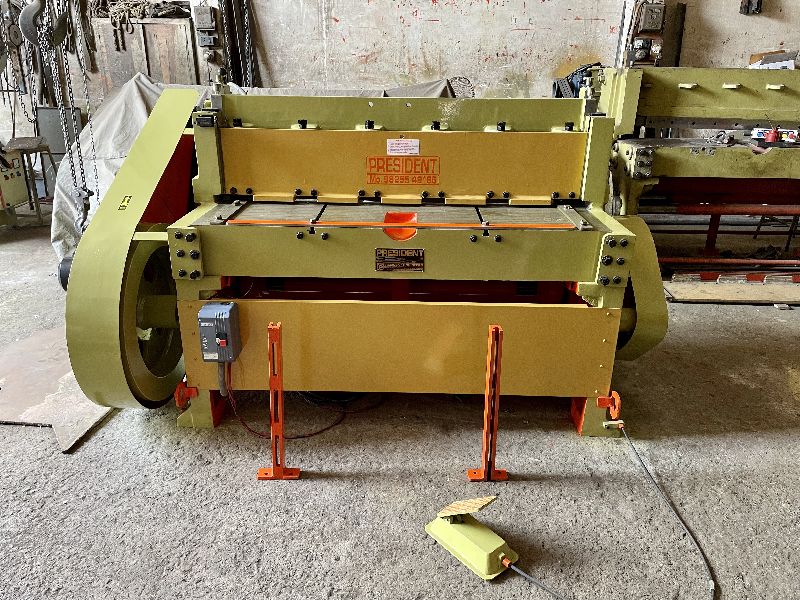

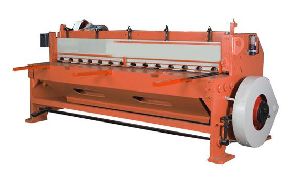

FRAME:

To ensure rigidity and accurate alignment to the complete assembly and to, unsure against vibrations and detractions, cast iron side walls having large dimensions and cross section, properly ribbed at critical places are provided. Except for side walls and all other parts are steel fabricated.

TABLE:

Steel fabricated, box type table is heavily ribbed for strength and is stress relived, Its machined seat provides true and firm support to the bottom blade. It is adjustable for setting the blade clearance. The top surface of the table is provided with T slots for adjusting the front guage.

UPPER BEAM:

Upper beam is fabricated with thick M. S. plate. It is heavily ribbed from behind and is stress relieved. The top blade is fitted at its accurately machined seat, its sliding surface are machined and hand scrapped for smooth travel and sustained accurately.

GUIDE WAYS:

Accurately machined guide ways keep the upper beam in its bearing throughout the stroke. A taper wedge is provided to compensate for the wear and to facilitate quick setting of the blade clearance.

HOLD DOWN DEVICE:

The spring-loaded mechanical hold down pads hold the sheet securely, to avoid slipping and bowing resulting in clean square cut, hold down units are provided with oversize pads to avoid impressions on sheet metal on request.

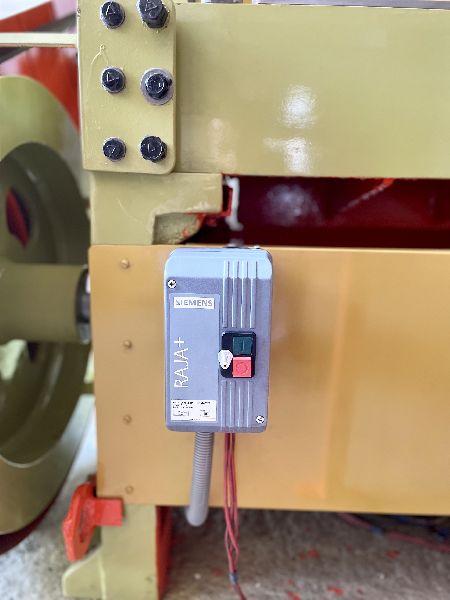

DRIVE, CLUTCH AND BRAKE: DRIVE:

Motor, mounted on an adjustable platform, drives the large cast iron fly wheel through vee belts. The power is further transmitted to the fly wheel shaft through steel pinion and main gear. Gun metal bushes are provided all the rotating parts.

CLUTCH:

Rolling key clutch is linked with the main gear and engages every time when the foot switch is pressed.

BRAKE:

spring tensioned brake fitted at the end of the crank shaft to damp inertia.

FRONT AND REAR GAUGES: FRONT GAUGE:

T Slotted front gauge fabricated from mild steel is detachable.

REAR GAUGE:

Rack and Pinion type rear gauge provides accuracy and is easily adjustable to cut parallel and taper strips efficiently.

BLADE:

President shears are provided with high quality single segment (Hc, hcr) blade with four edged.

LUBRICATION:

All bearing parts and guide surfaces are lubricated through connected oil cups and hand operated lubrication pump.

STANDARD EQUIPMENTS:

Rear gauge, Side squaring and Front gauge, Foot pedal switch,

Motor pully, Gear & Fly wheel guards, Standard instruction manual and Spanner.

STANDARD ACCESSORIES:

Electric Motor, Starter, Vee belts, Manual lubrication pump, Front gauge, Rear gauge with scale and stroke counter, Electric and lubricating pipe fittings and wiring.

POWER SUPPLY:

400 / 440 Volts, 3 Phase, 50 Cycles.

NOTE: Electrical items & blade are not under warranty.

Specification

| Model | Cutting capacity in Mild steel Length X Thickness |

Stroke Per Minute |

Table Height |

Table Width |

Front Gauge |

Rear Gauge |

Motor HP / KW |

Blade Length x Width x Thickness |

Overall Dimension in M.M.

|

|||||

| PUS-2/1 | 1270 x 2 | 45 | 795 | 350 | 750 | 500 | 2 / 1.5 | 1270 x 50 x 10 | 2030 | 1325 | 1350 | |||

| PUS-2/2 | 1525 x 2 | 45 | 795 | 350 | 750 | 500 | 2 / 1.5 | 1525 x 50 x 10 | 2300 | 1325 | 1350 | |||

| PUS-2/3 | 2030 x 2 | 45 | 795 | 350 | 750 | 500 | 3 / 2.2 | 2030 x 50 x 12 | 2800 | 1325 | 1350 | |||

| PUS-2/4 | 2540 x 2 | 45 | 810 | 425 | 975 | 500 | 5 / 3.7 | 2540 x 62 x 13 | 3300 | 1450 | 1450 | |||

| PUS-2/5 | 3125 x 2 | 45 | 810 | 425 | 975 | 500 | 7.5 / 5.6 | 3125 x 62 x 13 | 3900 | 1450 | 1450 | |||

| PUS-4/1 | 1270 x 4 | 50 | 810 | 425 | 975 | 500 | 5 / 3.7 | 1270 x 62 x 13 | 2100 | 1450 | 1400 | |||

| PUS-4/2 | 1525 x 4 | 50 | 810 | 425 | 975 | 500 | 5 / 3.7 | 1525 x 62 x 13 | 2400 | 1450 | 1400 | |||

| PUS-4/3 | 2030 x 4 | 50 | 810 | 425 | 975 | 500 | 7.5 / 5.6 | 2030 x 62 x 13 | 2900 | 1450 | 1400 | |||

| PUS-4/4 | 2540 x 4 | 50 | 900 | 450 | 975 | 600 | 10 / 7.7 | 2540 x 75 x 18 | 3400 | 1700 | 1550 | |||

| PUS-4/5 | 3125 x 4 | 50 | 900 | 450 | 975 | 600 | 12.5 / 9.7 | 3125 x 75 x 18 | 4000 | 1700 | 1550 | |||

| PUS-6/1 | 1270 x 6 | 50 | 810 | 425 | 975 | 500 | 7.5 / 5.6 | 1270 x 62 x 16 | 2150 | 1500 | 1400 | |||

| PUS-6/2 | 1525 x 6 | 50 | 810 | 425 | 975 | 500 | 10 / 7.7 | 1525 x 62 x 16 | 2450 | 1500 | 1400 | |||

| PUS-6/3 | 2030 x 6 | 50 | 900 | 450 | 975 | 600 | 12.5 x 9.7 | 2030 x 75 x 18 | 3950 | 1700 | 1600 | |||

| PUS-6/4 | 2540 x 6 | 50 | 900 | 450 | 975 | 600 | 12.5 x 9.7 | 2540 x 75 x 18 | 3450 | 1700 | 1600 | |||

| PUS-6/5 | 3125 x 6 | 50 | 900 | 450 | 975 | 600 | 15 x 11.2 | 3125 x 75 x 18 | 4100 | 1700 | 1600 | |||