Listing ID #5818387

Company Information

Ask for more detail from the seller

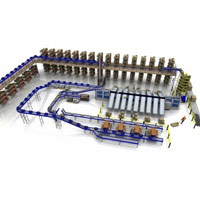

Contact SupplierLean Phase Pneumatic Conveying system, Dense Phase Pneumatic Conveying system

Plutontek, Designs & Manufactures, pneumatic conveying systems as a tailor made product, to provide solutions for bulk material handling. Design of system depends on the product characteristics, particle size, capacity, number of inlet sources and number of outlet / destinations, etc. Each pneumatic conveying system needs to be designed & customized as per the application given. Prime mover for conveying the product can be Roots blower, Compressor, Centrifugal blower, Centrifugal fan or Radial blower, depending upon bulk density of the material to carry, Length of the system, flow rate required and pressure required at outlet. System can run on both negative / positive pressure, depending upon the situation.

At Plutontek, we have to consider all the given parameters to design the system and has to offer the optimum solution to customer in order to achieve economies in intial cost as well as running cost

You can rely on us for all your customized requirements of :

"Dense Phase Pneumatic Conveying system :

"Lean Phase (Dilute Phase) Pneumatic Conveying system :

"Combined Lean phase and dense phase pneumatic conveying system

This system uses both - Combination of Negative - Positive Pressure i.e. pull-push system which has the advantages and benefits of both negative and positive pressure arrangements in a single system. These systems are used where there are multiple material entry points, and multiple delivery points. A very common application is the unloading of a standard railcar. This system of conveying is given only on specific customer demands."