Listing ID #3790737

Company Information

Ask for more detail from the seller

Contact Supplier|

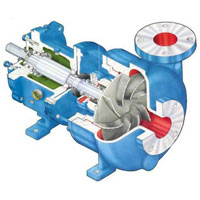

Leveraging on our expertise, we manufacture and fabricate quality Chemical Process Pumps. Our range of pumps find a wide application in chemicals, petrochemicals, fertilizers, oil refineries, paper mills, sugar mills, dairy, pesticides, pharmaceutical industries and steel plants. Apart from manufacturing, we also provide fabrication services to our clients. Depending on the nature of the liquid to be handled, we accordingly seal and pack the product. Our range of chemical pumps are widely known for high performance and reliability.

|

| Plastic Moulded Pumps ( Series FPP & FTP ) |

|

We are instrumental in providing a variety of Plastic Molded Pumps, which is best suited to be used for corrosive acids & alkalies effluent treatment plant. Manufactured using high-grade P.P., U.H.M.W.P.E.and P.V.D.F. granules. it conforms to international quality standards. Our range of Plastic Molded Pumps is available in varied specifications and finds application in the following segments:

|

|

Specifications:

Following are the quality attributes of our range: