Listing ID #6806265

Company Information

Ask for more detail from the seller

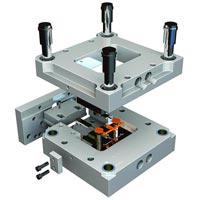

Contact SupplierProcess Overview – Injection molding is a manufacturing process in which molten plastic is injected into a mold which is made up of steel or aluminum. Principally it is like a die casting process used for making metal parts. The semi-molten plastic is injected into a feeding system and traversed to the mold before passing through feed, transition, and metering section. The Injection molding process cycle consist of six main stages :

Closing of mold – When the mold is closed the injection molding cycle timer begins

Injection - Heated plastic is injected into the mould. As the melt enters the mould, the displaced air escapes through vents in the injection pins and along the parting line. A good runner, gate and vent design are important to ensure the mould is properly filled.

Cooling - Once the mould is filled the part is allowed to cool for the exact amount of time needed to harden the material. Cooling time is dependent on the type of resin used and the thickness of the part.

Plasticizing the resin - While the part cools, the barrel screw retracts and draws new plastic resin into the barrel from the material hopper. The heater bands maintain the needed barrel temperature for the type of resin being used.

Ejection - The mould opens, and the ejector rod moves the ejector pins forward. The part falls and is captured in a bin located below the mould.

Removing the runner – Runners and gates are removed from the original part. Runners are also ground and recycled to reduce costs and environmental impact.

Capabilities

Integrated sequential manufacturing process under one roof i.e., Simulation -> Tool designing and manufacturing -> Prototype -> Mass production

Tool room equipped with VMC’s and CNC’s for manufacturing of die and molds

Prototype to high volume production of up to millions of parts per year based on part configuration

Manufacturing of parts wide variety of materials such as ABS, LDPE, HDPE, Nylon, PC etc.

Manufacturing of molds for up to 3000 Ton molding machine

Provide different type of finish to molded part based on customer requirement

CMM inspection for part validation and approval

In-house lab tests carried out for raw material verification at production site, certified to international standards

Defect analysis of plastic molded parts as per international standards

Customer appointed third party inspection and verification allowed

Manufacturing facility certified to IATF 16949 and ISO 13485 Quality Management System

Implementation of Lean Six Sigma tools for better quality control, process control, part traceability and documentation

Industry 4.0 integrated manufacturing facilities

Application and Benefits

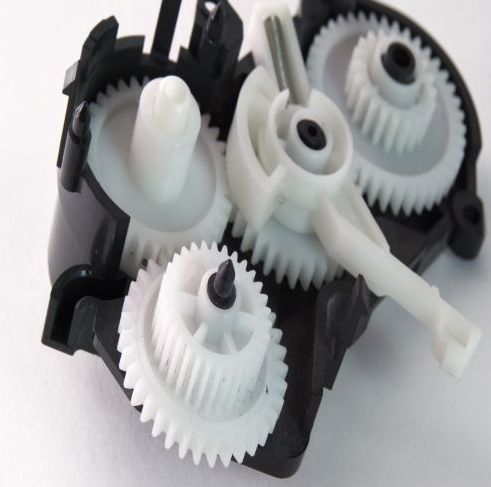

Injection molded parts have vast application in consumer and commercial products which are used by us in our daily lives. Few commonly known parts include :

Automotive parts – Dashboards, bumpers, grills

Electronic components – Connectors, enclosures, protective sleeving

Medical devices – Syringes, valves, dishes

Consumer plastics – Mobile covers, bottles, toys

Furniture – Seat covers, cushions, chairs

Few important benefits of plastic injection molding are :

Highly efficient mass production

Low production cost

Manufacturing of complex and intricate parts

Enhanced material strength

Flexibility of material and color selection

Reduced material wastage

Established in the year 2021 with an aim to provide end to end manufacturing assistance to Technology and Engineering companies located overseas for their product development cycle. The Company has a manufacturing setup in the prime location of Navi Mumbai giving it a strategic access to an extensive supplier network catering across industry sectors such as Aerospace, Automobile, Steel, Energy, Plastic etc. and correspondingly providing an excellent connectivity to our overseas customer through Air and Sea.

We are committed to provide the finest of manufacturing experiences with minimal intricacies and management troubles. We work with you to co-create innovative and futuristic products while ensuring 100% delivery of its value & service. We have established a global ecosystem comprising of : critical part suppliers, outsourcing vendors, business partners, industry experts and consultants having expertise across wide range of industry domains such as castings, forgings, additive manufacturing, machining, welding, heat treatment, surface engineering, sheet metal, tool and die making, plastics and polymer, electronics and automation etc.

Our Vision

Establishes an ecosystem for holistic development of innovative, breakthrough and futuristic products.

Our Mission

Provide World Class Manufacturing services to at least 100 customers by the year 2025

Quality Assurance

At Innowerx, Quality consciousness is at the heart of each business activity. We have a structured and well-defined Quality Management System in accordance with ISO 9001:2015 and AS 9100 Rev.D standards. Customer requirements are thoroughly reviewed, clearly documented, and effectively communicated down the supply chain to ensure 100% compliance at the end of project/product life cycle. The quality tools implemented by us to ensure zero defects and zero customer complaints.

Our Leadership

A true visionary entrepreneur with great leadership qualities and the zest to focus on perfection, excellence, and smart work. His goal is to create a legacy and have the ability to contribute to the society through his vigor and work. Having had a total work-ex of 8 years, Mr. Kudva started his professional journey as a Production Engineer to get deep insights on the manufacturing challenges that are faced by the industry. Slowly developing a passion for problem solving and business management he took on to the leadership role in our sister concern Associated Plasmatron Private Limited as the Administrative Director in just a span of 5 years. While acting in this role he has been able to formulate business targets, restructured the Quality Management System and got the Company certified for AS 9100; correspondingly having faced the AS 9100 audits for 4 consecutive years and has aced well at every juncture.

He has been able to redefine the business process flow and automated it through a customized online ERP system; won several accolades for the Company, organized by Clients and Industry Associations such as the Most Sustainable Partner Award and SME National Productivity Championship. A Mechanical Engineer passed out from Mumbai University, he continued to develop his industrial skill set through various certification courses. Alongside, he holds a postgraduate qualification in MBA and is an alumnus at the S.P. Jain Institute of Management, Mumbai which has given him major backing and knowledge about the business world.