Listing ID #1201655

Company Information

Ask for more detail from the seller

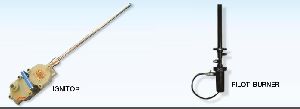

Contact SupplierWe manufacture export and supply high quality Pilot Burners that are made in accordance to the internationally approved standards. These Pilot Burners are highly efficient and offer long term usage. We manufacture these Pilot Burners with the use of high grade raw material for durability and efficiency.

Safety System for Heaters : (Similar to MIs Invalco/Natco Stock No. 48362445) low Temperature Shut Down Device

Introduction

Low temperature shut down device is basically PilotBurner shut offsystem. The pilot Burner helps to light the main burner. In case pilot Burner is shut, the main burner will not light and this will cause accumulation of Gas in the vessel. There can be backfiring when operator lights the main burner. To avoid this situation, pilot Burner shut off system with alarm and gas shut down valve is used which consists of following :