Listing ID #5388328

Company Information

Ask for more detail from the seller

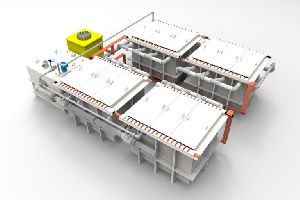

Contact SupplierThe aim of Pre-treatment & Bleaching is to remove minor constituents namely phospholipids, heavy metals and other oxidative components prior to Deacidification/ Deodorization.

Specially designed Pre-treatment & Continuous Bleaching Plant by MECTECH is cost effective and ensures perfect results. Equipment for Pretreatment & Refining designed by MECTECH ensures deacidification by distillation of free fatty acids combined with partial or complete deodorization. Mectech is one of the top Oil Deodorization Systems manufacturers & Deodorizing Plants suppliers in India and abroad.

Deacitification / Deodorization