Listing ID #4905449

Company Information

Ask for more detail from the seller

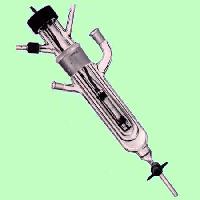

Contact SupplierAmar Equipments Pvt. Ltd. are largest manufacturer of Metal Flow Reactors in India. With Knowledge of more than 4 years infield of Flow Chemistry and based on research and development of various reactions; we at Amar, have combined the advantages of continuous flow processing with the added benefits of ultraviolet light to enable photochemical reactions and a consistent distribution of UV light to ensure

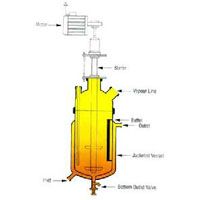

One of the key issues of scaling-up organic photochemistry in an immersion-well (batch) reactor is that light penetration to the surrounding solution is limited by the high absorption of the substrate and falls off rapidly with distance from the lamp. Essentially the reaction solution nearest the lamp screens the bulk of the reaction solution from UV. This effect is also amplified if the reaction solution is concentrated. When the scale of the reaction is increased with the same lamp it becomes increasingly more difficult to drive the reaction to completion. Attempts to do sooften result in over-irradiation of the product and formation of side products and photopolymers.

This is where flow photochemistry becomes a very attractive proposition, as in principle it can overcome all the key problems of batch photochemistry.

Features

Applications