Company Information

Ask for more detail from the seller

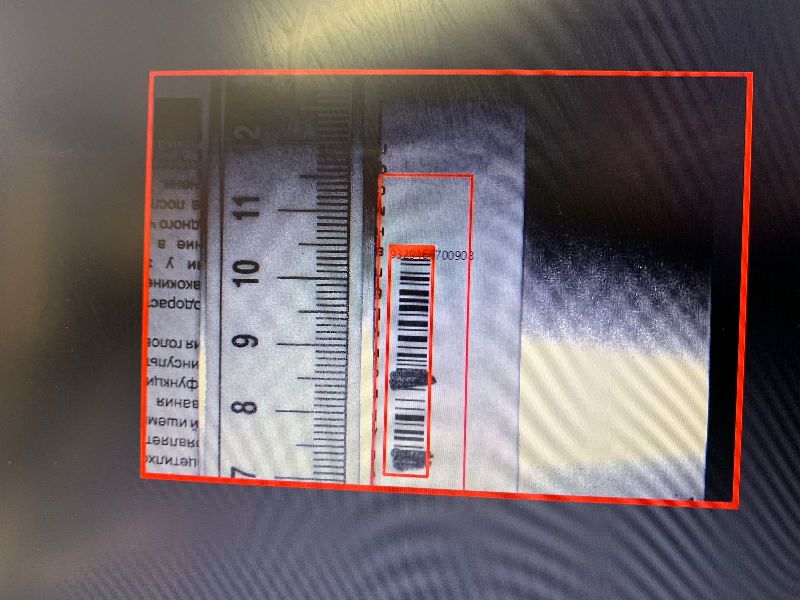

Contact Supplierpharmacode inspection system for inserts and outserts suitable for pharmacodes , barcodes and blank sheets description: a) absolute basic (blank sheet detection) - this budget-friendly top bottom camera system includes 2 small cameras, a 15 “ capacitive touchscreen industrial panel compute (fanless), sensor, mountings, and a straightforward controller. - the machine will stop if one of the cameras notices a blank page (no printing). - it is a very straightforward and dependable device that stops blank sheets. 2. basic system: this system is made up of the following parts: - 1 baumer sensor - 15" capacitive touchscreen fanless ipc - basic controller - cables & mountings - 2 baumer hhs smart cameras with one significant exception, this system is comparable to the very basic system. the cameras are capable of the following tasks: - pattern matching (good for detecting blank sheets, inspecting orientation, and detecting mix-ups***) - reading 1d codes, including pharmacode - reading 2d codes the live images and individual camera counts are shown in this system. this system doesn't have a database, information on jobs, or reports. high quality camera based and ipc inspection and rejection system with 21 cfr part 11 compliant can be able to show faulty or rejected pharmacodes / barcodes and also can able to see live screening of ongoing jobs batchwise counting . all data report including user security batch making , job types , receipe batch , total rejected and accepted counts . which can able to see overall production of the machine per day as per required time. 3. advanced system: the components of this system 2. baumer hhs smart cameras. 1. baumer sensor. encoder. 10.4" capacitive touchscreen fanless ipc. advanced vision controller. cables & mountings. advanced vision inspection software. the same inspection is performed by this system as it does by the basic system mentioned above, but it also includes a user interface specifically created for folding machine inspection. the ui shows real-time photographs as well as total camera counts from both, product specifications, etc. the technology also includes a database that stores the job's progress even in the event of a power outage. furthermore, user login passwords are used to secure the system. details including product identifier, batch number, user identifier, good/bad/total counts patter match, 1d code, 2d code, and the code value of each camera are inspection tools. - job start, make ready, and job finish timestamps - be prepared to count – acceptance/rejection by qc, etc. the reports can always be downloaded to a usb flash drive. the following characteristics of 21cfr part 11 compliance, which can be incorporated to this system, the vision inspection system designed to perform not serialized linear and 2d codes inspection (eg. pharmacode barcodes and others), ocv/ocr characters checks on variable data and special customized controls on the packaging aspect by using the programmable measures tool. it is a complete solution, delivering the best powerful inspection performance in ultra-compact miniaturized hardware. originally designed for the integration into folding machines. we are as manufacturer, supplier and exporter of leaflet folding machine we can able to provide pharmacode inspection system with this folding machine . our sensor based system checks printing errors in codes and avoids mixups online. a small, lightweight , compact sensor is used which is capable of inspection at very high speeds. being a sensor based solution, it requires minimum involvement by the operator.this solution also helps to keep track of the total leaflets s that were rejected for mixups or misregistration of the pharmacode . it has been specifically designed to meet the requirements of the pharmaceutical industry.this is an essential tool for all designers and printers of pharmaceutical packaging. our inspection system en