Listing ID #6070399

Company Information

Ask for more detail from the seller

Contact SupplierHarmaceutical manufacturing is a highly controlled and regulated process. Almost every process can be automated and there have been rapid and continuous advancements in the solid dosage manufacturing processes. Major manufacturers are constantly assessing their competitiveness to ensure constant growth in an ever more demanding market where the cost of developing novel products is continuously increasing. There has been an urgent need for pharma companies to continuously invest in innovative processes to produce solid dosage forms that better meet the needs of the patient and are efficiently manufactured.

Oral dosage forms oral dosage forms including the tablets and capsules are considered the most patient acceptable dosage forms in the market today. They offer convenience and ease of handling and are also extremely stable, both chemically and physically. Production of these solid dosage drugs is also relatively inexpensive and high throughput is well achieved.

Granulation process pharmaceutical granulation is necessary to overcome the significant compression difficulties and erratic flow properties of many active pharmaceutical ingredients (api, s) that limit the successful production of these dosage forms.

Current solid dosage manufacturing technologies orally administered solid dosage forms constitute a blend of several pharmaceutical excipients. These include diluents, binders, disintegrants, glidants, lubricants, and the api’s. Successful production of these types of products is dependent on the ability of the production process to adequately mix and or granulate these products to ensure that the resultant solid agglomerates posses high fluidity , compressibility and in addition avoid de-mixing during the following post granulation processes such as tablet compression and capsule filling processes.

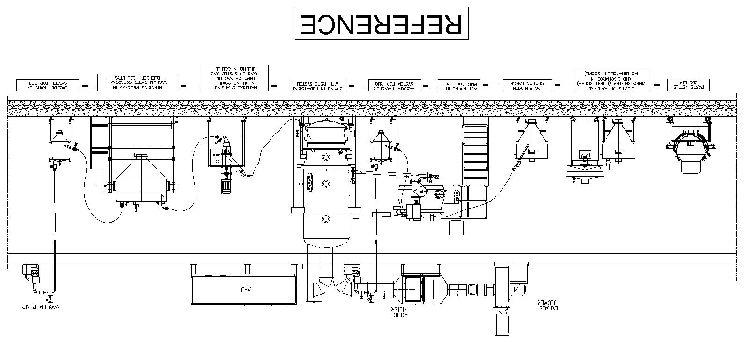

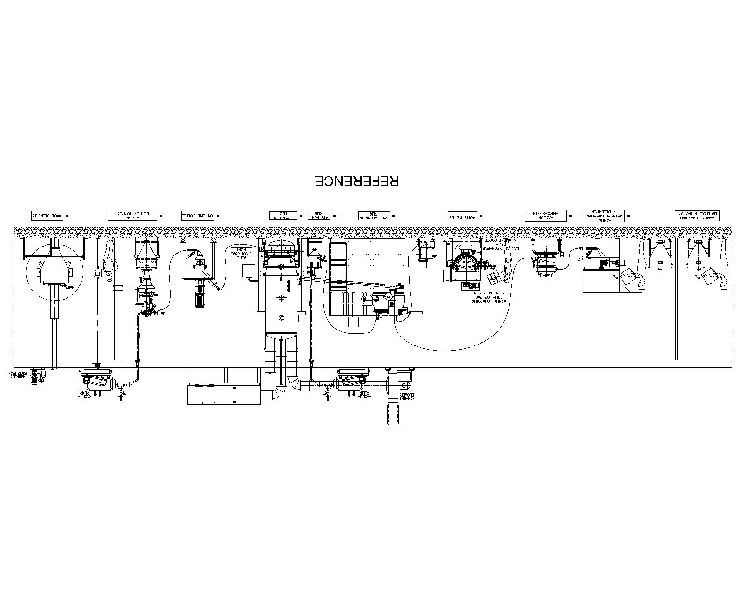

Manufacturing equipments the production equipment forms a critical part in the success of the process. They must be able accurately determine, define and release product in accordance to the calibrated quantities without altering any properties of the products. Some of the solid dosage manufacturing equipments include; storage tanks, jacketed vessels, tablet coating machine, vibro-sifters, multi mills, de burring, de dusting machine, oscillating granulator, granulating machine, tablet coating, pan tablet coating machine, strip packing machines, blister packaging machinery, liquid filling machinery, liquid manufacturing plants and many more.

Emerging manufacturing trends wet granulation process is a relatively newer and better technology. It encompasses low and high shear mixing, fluid bed mixing and wet mass extrusion and is more versatile compared to other methods. This process has improved control of drug content, better uniformity and also produces granules with the superior bulk density and compatibility.

Research and analysis the use of process analytical technology (pat) in production of powders has helped in the understanding and improvement of processing technologies. Recent advances in technology have enabled real-time process monitoring and needed adjustments are made on time

optimizing solid dosage manufacturing; continuous processing continuous processing for solid dosage manufacturing is a rapidly growing concept. The advancement in the processing equipments such as the oscillating granulators, strip packing machines, blister packaging machinery, liquid filling machinery, liquid manufacturing plants and many more has made continuous manufacturing a current reality. This method of processing is most preferred because it has a low residence time, variables can be changed and the results can be explored rather quickly. The implementation of continuous manufacturing as opposed to batch processing is now much easier and cost effective. The scaling up process is also easier due to better control of the equipments.